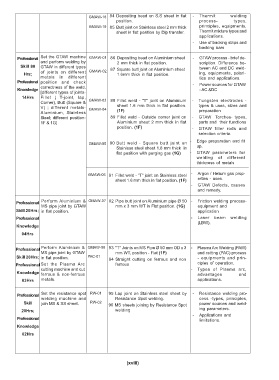

Page 20 - Welder - TT - Gujarati

P. 20

GMAW-18 84 Depositing bead on S.S sheet in flat - Thermit welding

position. process- types,

GMAW-19 85 Butt joint on Stainless steel 2 mm thick principles, equipments,

sheet in flat position by Dip transfer. Thermit mixture types and

applications.

- Use of backing strips and

backing bars

Professional Set the GTAW machine GMAW-01 86 Depositing bead on Aluminium sheet - GTAW process - brief de-

and perform welding by 2 mm thick in flat position. scription. Difference be-

Skill 80 GTAW in different types 87 Square butt joint on Aluminium sheet tween AC and DC weld-

Hrs; of joints on different GMAW-02 1.6mm thick in flat position. ing, equipments, polari-

metals in different ties and applications.

Professional position and check - Power sources for GTAW

Knowledge correctness of the weld. - AC &DC

[different types of joints-

14Hrs Fillet ( T-joint, lap,

Corner), Butt (Square & GMAW-03 88 Fillet weld - "T" joint on Aluminium - Tungsten electrodes -

V) ; different metals- GMAW-04 sheet 1.6 mm thick in flat position. types & uses, sizes and

Aluminium, Stainless (1F) preparation

Steel; different position- 89 Fillet weld - Outside corner joint on - GTAW Torches- types,

1F & 1G] Aluminium sheet 2 mm thick in flat parts and their functions

position. (1F) - GTAW filler rods and

selection criteria.

GMAW-05 90 Butt weld - Square butt joint on - Edge preparation and fit

Stainless steel sheet 1.6 mm thick in up.

flat position with purging gas (1G) - GTAW parameters for

welding of different

thickness of metals

GMAW-06 91 Fillet weld - "T" joint on Stainless steel - Argon / Helium gas prop-

sheet 1.6 mm thick in flat position. (1F) erties - uses.

- GTAW Defects, causes

and remedy.

Professional Perform Aluminium & GMAW-07 92 Pipe butt joint on Aluminium pipe Ø 50 - Friction welding process-

MS pipe joint by GTAW mm x 3 mm WT in Flat position. (1G) equipment and

Skill 20Hrs; in flat position. application

Professional - Laser beam welding

(LBW).

Knowledge

04Hrs

Professional Perform Aluminium & GMAW-08 93 "T" Joints on MS Pipe Ø 50 mm OD x 3 - Plasma Arc Welding (PAW)

MS pipe joint by GTAW mm WT, position - Flat (1F) and cutting (PAC) process

Skill 20Hrs; in flat position. PAC-01 94 Straight cutting on ferrous and non - equipments and prin-

Professional Set the Plasma Arc ferrous ciples of operation.

cutting machine and cut - Types of Plasma arc,

Knowledge ferrous & non-ferrous advantages and

03Hrs metals. applications.

Professional Set the resistance spot RW-01 95 Lap joint on Stainless steel sheet by - Resistance welding pro-

welding machine and Resistance Spot welding. cess -types, principles,

Skill join MS & SS sheet. RW-02 96 MS sheets joining by Resistance Spot power sources and weld-

20Hrs; welding ing parameters.

- Applications and

Professional limitations.

Knowledge

02Hrs

(xviii)