Page 16 - Content.pmd

P. 16

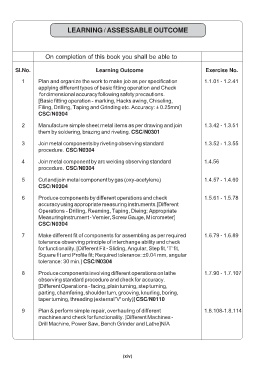

LEARNING / ASSESSABLE OUTCOME

On completion of this book you shall be able to

SI.No. Learning Outcome Exercise No.

1 Plan and organize the work to make job as per specification 1.1.01 - 1.2.41

applying different types of basic fitting operation and Check

for dimensional accuracy following safety precautions.

[Basic fitting operation - marking, Hacks awing, Chiseling,

Filing, Drilling, Taping and Grinding etc. Accuracy: ± 0.25mm]

CSC/N0304

2 Manufacture simple sheet metal items as per drawing and join 1.3.42 - 1.3.51

them by soldering, brazing and riveting. CSC/N0301

3 Join metal components by riveting observing standard 1.3.52 - 1.3.55

procedure. CSC/N0304

4 Join metal component by arc welding observing standard 1.4.56

procedure. CSC/N0304

5 Cut and join metal component by gas (oxy-acetylene) 1.4.57 - 1.4.60

CSC/N0304

6 Produce components by different operations and check 1.5.61 - 1.5.78

accuracy using appropriate measuring instruments.[Different

Operations - Drilling, Reaming, Taping, Dieing; Appropriate

MeasuringInstrument - Vernier, Screw Gauge, M icrometer]

CSC/N0304

7 Make different fit of components for assembling as per required 1.6.79 - 1.6.89

tolerance observing principle of interchange ability and check

for functionality. [Different Fit - Sliding, Angular, Step fit, 'T' fit,

Square fit and Profile fit; Required tolerance: ±0.04 mm, angular

tolerance: 30 min.] CSC/N0304

8 Produce components involving different operations on lathe 1.7.90 - 1.7.107

observing standard procedure and check for accuracy.

[Different Operations - facing, plain turning, step turning,

parting, chamfering, shoulder turn, grooving, knurling, boring,

taper turning, threading (external 'V' only)] CSC/N0110

9 Plan & perform simple repair, overhauling of different 1.8.108-1.8.114

machines and check for functionality. [Different Machines -

Drill Machine, Power Saw, Bench Grinder and Lathe]N/A

(xiv)