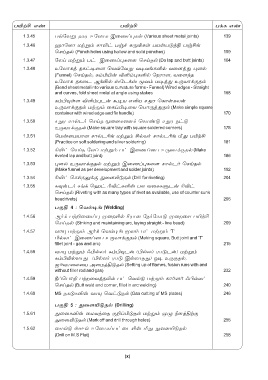

Page 12 - Content.pmd

P. 12

T«t£ Gi T«t£ TdL Gi

1.3.45 TpúYß RLW EúXôL CûQl×Ls (Various sheet metal joints) 139

1.3.46 aôúXô Utßm NôXõh Tgf LÚ®Ls TVuTÓj§ Tg£e

ùNnRp (Punch holes using hollow and solid punches) 159

1.3.47 úXl Utßm Th CûQl×Lû[ ùNnRp (Do lap and butt joints) 164

1.3.48 EúXôLj RLh¥û] ùYqúYß Y¥YeL°p Yû[jÕ ×]p

(Funnel) ùNnRp, Lm©«u ®°m×L°p úSWô], Yû[kR

EúXôL RLûP Be¡p vúPdv êXm U¥jÕ EÚYôdÏRp

(Bend sheet metal into various curvature forms - Funnel) Wired edges - Straight

and curves, fold sheet metal at angle using stakes 168

1.3.49 Lm©Ùs[ ®°m×Pu á¥V G°V NÕW ùLôsLXu

EÚYôdÏRp Utßm ûLl©¥ûV ùTôÚjÕRp (Make simple square

container with wired edge and fix handle) 170

1.3.50 NÕW NôpPo ùNnR êûXLû[d ùLôiÓ NÕW RhÓ

EÚYôdÏRp (Make square tray with square soldered corners) 178

1.3.51 ùUuûUVô] NôpP¬e Utßm £pYo NôpP¬e ÁÕ T«t£

(Practice on soft soldering and silver soldering) 181

1.3.52 ¬®h ùNnR úXl Utßm Th CûQlûT EÚYôdÏRp (Make

riveted lap and butt joint) 186

1.3.53 ×]p EÚYôdÏRp Utßm CûQl×Lû[ NôpPo ùNnRp

(Make funnel as per development and solder joints) 192

1.3.54 ¬®h ùNnRÛdÏ Õû[«ÓRp (Drill for riveting) 204

1.3.55 LÜuPo Ned ùah ¬®hL°u TX YûLLÞPu ¬®h

ùNnRp (Riveting with as many types of rivet as available, use of counter sunk

head rivets) 206

Tϧ 4 : ùYp¥e (Welding)

1.4.56 Bod Tt±ûQl× Øû\«p ºWô] úSoúLôÓ Øû\ûV T«t£

ùNnRp (Striking and maintaining arc, laying straight - line bead) 209

1.4.57 YôÙ Utßm Bod ùYp¥e êXm Th Utßm ‘T’

©pXh CûQlûT EÚYôdÏRp (Making square, Butt joint and ‘T’

fillet joint - gas and arc) 215

1.4.58 YôÙ Utßm @©pXo Lm©ÙPu (©pXo WôÓPu) Utßm

Lm©«pXôÕ (©pXo WôÓ CpXôRÕ) J¥ EÚÏRp,

_øYôûXûV AûUj§ÓRp (Setting up of flames, fusion runs with and

without filler rod and gas) 232

1.4.59 ¾lùTô± Tt\ûYjRXõp Th ùYpÓ Utßm Lôo]o @©pXh

ùNnRp (Butt weld and corner, fillet in arc welding) 240

1.4.60 MS RLÓL°u YôÙ ùYhÓRp (Gas cutting of MS plates) 246

Tϧ 5 : Õû[«ÓRp (Drilling)

1.5.61 Õû[L°u ûUVjûR ϱl©ÓRp Utßm ØÝ ¿[j§tÏ

Õû[«ÓRp (Mark off and drill through holes) 255

1.5.62 ûUpÓ v¼p EúXôLlThûP«u ÁÕ Õû[«ÓRp

(Drill on M.S Flat) 258

(x)