Page 19 - Foundryman - TP - Hindi

P. 19

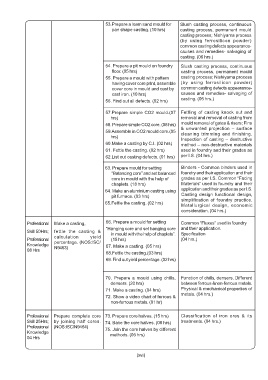

53.Prepare a loam sand mould for Slush casting process, continuous

pan shape casting. (10 hrs) casting process, permanent mould

casting process; Nishiyama process

(by using ferrosilicon powder)

common casting defects appearance-

causes and remedies- salvaging of

casting. (06 hrs.)

54. Prepare a pit mould on foundry Slush casting process, continuous

floor. (05 hrs) casting process, permanent mould

55. Prepare a mould with pattern casting process; Nishiyama process

having cover core print, assemble (by using ferrosilicon powder)

cover core in mould and cast by common casting defects appearance-

cast iron. (10 hrs) causes and remedies- salvaging of

casting. (06 hrs.)

56. Find out all defects. (02 hrs)

57.Prepare simple CO2 mould.(07 Fettling of casting knock out and

hrs) removal and removal of casting from

58. Prepare simple CO2 core. (08 hrs) mould removal of gates & risers; Fins

59.Assemble in CO2 mould core.(05 & unwanted projection – surface

cleaning trimming and finishing.

hrs)

Inspection of casting – destructive

60.Make a casting by C.I. (02 hrs) method – non-destructive materials

61. Fettle the casting. (02 hrs) used in foundry and their grades as

62.List out casting defects. (01 hrs) per I.S. (04 hrs.)

63. Prepare mould for setting Binders - Common binders used in

“Balancing core” and set balanced foundry and their application and their

core in mould with the help of grades as per I.S. Common “Facing

chaplets. (18 hrs) Materials” used in foundry and their

64. Make an aluminium casting using application and their grades as per I.S.

pit furnace. (03 hrs) Casting design functional design,

simplification of foundry practice.

65.Fettle the casting. (02 hrs)

Metallurgical design, economic

consideration. (04 hrs.)

Professional Make a casting, 66. Prepare a mould for setting Common “Fluxes” used in foundry

“Hanging core and set hanging core and their application.

Skill 50Hrs; fettle the casting & in mould with the help of chaplets”. Specification

calculation yield

Professional percentage. (NOS:ISC/ (15 hrs) (04 hrs.)

Knowledge N9463) 67. Make a casting. (05 hrs)

08 Hrs

68.Fettle the casting.(03 hrs)

69. Find out yield percentage. (02 hrs)

70. Prepare a mould using chills, Function of chills, densers. Different

densers. (20 hrs) between ferrous &non-ferrous metals.

71. Make a casting. (04 hrs) Physical & mechanical properties of

metals. (04 hrs.)

72. Show a video chart of ferrous &

non-ferrous metals. (01 hr)

Professional Prepare complete core 73. Prepare core halves. (15 hrs) Classification of iron ores & its

Skill 25Hrs; by joining half cores. 74. Bake the core halves. (05 hrs) treatments. (04 hrs.)

Professional (NOS:ISC/N9464) 75. Join the core halves by different

Knowledge methods. (05 hrs)

04 Hrs

(xvii)