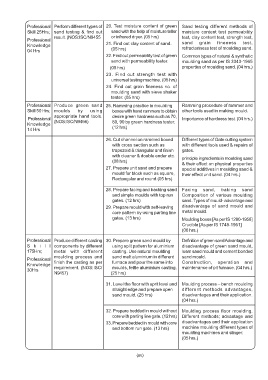

Page 17 - Foundryman - TP - Hindi

P. 17

Professional Perform different types of 20. Test moisture content of green Sand testing different methods of

Skill 25Hrs; sand testing & find out sand with the help of moisture teller moisture content test permeability

result. (NOS:ISC/N9455 or infrared dryer. (05 hrs) test, clay content test, strength test,

Professional sand grain fineness test,

Knowledge 21. Find out clay content of sand. refractoriness test of moulding sand.

04 Hrs (05 hrs)

22. Find out permeability test of green Common types of natural & synthetic

sand with permeability tester. moulding sand as per IS 3343-1965

(05 hrs) properties of moulding sand. (04 hrs.)

23. Find out strength test with

universal testing machine. (05 hrs)

24. Find out grain fineness no. of

moulding sand with sieve shaker

tester. (05 hrs)

Professional Produce green sand 25. Ramming practice in moulding Ramming procedure of rammer and

Skill 50 Hrs; moulds by using boxes with hand rammers to obtain other tools used in making mould.

appropriate hand tools. desire green hardness such as 70,

Professional Importance of hardness test. (04 hrs.)

Knowledge (NOS:ISC/N9456) 80, 90 by green hardness tester.

14 Hrs (12 hrs)

26. Cut channel on rammed boxed Different types of Gate cutting system

with cross section such as with different tools used & repairs of

trapezoid & triangular and finish gates.

with cleaner & double ender etc. principle ingredients in moulding sand

(08 hrs) & their effect on physical properties

27. Prepare unit sand and prepare special additives in moulding sand &

mould for block such as square, their effect unit sand. (04 hrs.)

Rectangular and round.(05 hrs)

28. Prepare facing and backing sand Facing sand, baking sand

and simple moulds with top run Composition of various moulding

gates. (12 hrs) sand. Types of mould- advantage and

29. Prepare mould with self-leaving disadvantage of sand mould and

core pattern by using parting line metal mould.

gates. (13 hrs) Moulding boxes [As per IS 1280-1958]

Crucible [As per IS 1748-1961]

(06 hrs.)

Professional Produce different casting 30. Prepare green sand mould by Definition of green sand Advantage and

Skill components by different using split pattern for aluminium disadvantage of green sand mould,

175Hrs; metal with different casting. Use natural moulding loam sand mould and cement bonded

moulding process and sand melt aluminium in different sand mould.

Professional finish the casting as per furnace and pour the same into Construction, operation and

Knowledge requirement. (NOS:ISC/ moulds, fettle aluminium casting. maintenance of pit furnace. (04 hrs.)

30Hrs

N9457) (25 hrs)

31. Level the floor with sprit level and Moulding process – bench moulding

straight edge and prepare open different methods advantages,

sand mould. (25 hrs) disadvantages and their application.

(04 hrs.)

32. Prepare bedded in mould without Moulding process floor moulding.

core with parting line gate. (12 hrs) Different methods; advantage and

33. Prepare bedded in mould with core disadvantages and their application

and bottom run gate. (13 hrs) machine moulding different types of

moulding machines and slinger.

(05 hrs.)

(xv)