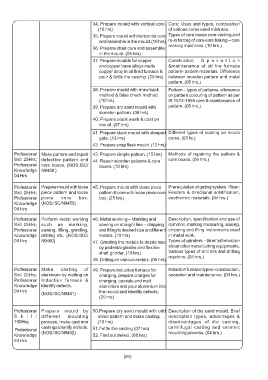

Page 18 - Foundryman - TP - Hindi

P. 18

34. Prepare mould with vertical core. Core: Uses and types, composition

(10 hrs) of various cores sand mixtures.

35. Prepare mould with horizontal core Types of core boxes core venting and

and assemble in the mould.(10 hrs) re-in forcing of core-core baking – core

making machines. (10 hrs.)

36. Prepare chair core and assemble

in the mould. (05 hrs)

37. Prepare moulds for copper Construction: O p e r a t i o n

andcopper base alloys melts &maintenance of oil fire furnace

copper alloy in oil fired furnace & pattern- pattern materials. Difference

pour & fettle the casting. (25 hrs) between wooden pattern and metal

pattern. (05 hrs.)

38. Prepare mould with draw back Pattern – types of patterns- allowance

method & false check method. on pattern colouring of pattern as per

(10 hrs) IS 1513-1959 care & maintenance of

39. Prepare dry sand mould with pattern. (05 hrs.)

skeleton pattern. (08 hrs)

40. Prepare black wash & coat on

mould. (07 hrs)

41. Prepare stack mould with steeped Different types of coating on mould

gate. (13 hrs) cores. (01 hr.)

42. Prepare snap flask mould. (12 hrs)

Professional Make pattern and repair 43. Prepare simple pattern. (15 hrs) Methods of repairing the pattern &

Skill 25Hrs; defective pattern and 44. Repair wooden patterns & core core boxes. (04 hrs.)

Professional core boxes. (NOS:ISC/ boxes. (10 hrs)

Knowledge N9458 )

04 Hrs

Professional Prepare mould with loose 45. Prepare mould with loose piece Prerequisites of gating system. Riser:

Skill 25Hrs; piece pattern and loose pattern & core with loose piece core Feeders & directional solidification,

Professional piece core box. box. (25 hrs) exothermic materials. (04 hrs.)

Knowledge (NOS:ISC/N9459)

04 Hrs

Professional Perform metal working 46. Metal working – Marking and Description, specification and use of

Skill 25Hrs; such as marking, sawing on straight line – chipping common, marking measuring, sawing,

Professional sawing, filling, grinding, and filling to desired size on different chipping and filing instruments used

Knowledge drilling etc. (NOS:ISC/ metals. (10 hrs) in metal work.

04 Hrs N9460) 47. Grinding the metals to desire size Types of grinders – Brief information

by pedestal grinder and flexible about other metal cutting equipments.

shaft grinder. (10 hrs) Various types of drill bits and drilling

machine. (04 hrs.)

48. Drilling on various metals. (05 hrs)

Professional Make casting of 49. Prepare induction furnace for Induction furnace types- construction,

Skill 25Hrs; aluminum by melting on charging, prepare charges for operation and maintenance. (04 hrs.)

Professional Induction furnace & charging, operate and melt

Knowledge identify defects. aluminium and pour aluminium into

04 Hrs the mould and identify defects.

(NOS:ISC/N9461)

(25 hrs)

Professional Prepare mould by 50.Prepare dry sand mould with odd Description of dry sand mould. Brief

Skill different moulding sided pattern and make casting. description types, advantages &

100Hrs; process, make cast iron (10 hrs) disadvantages of die casting,

castings identify defects. centrifugal casting and ceramic

Professional (NOS:ISC/N9462) 51.Fettle the casting (07 hrs) moulding process. (04 hrs.)

Knowledge 52. Find out defect. (08 hrs)

24 Hrs

(xvi)