Page 14 - Welder - TT - Gujarati

P. 14

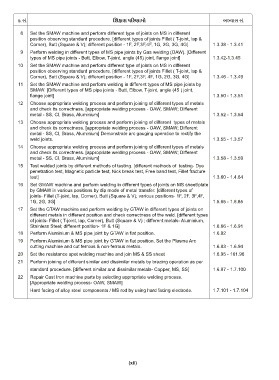

રિ. ્સં. શશક્ષણ પડરણામો અભ્યા્સ ્સં.

8 Set the SMAW machine and perform different type of joints on MS in different

position observing standard procedure. [different types of joints Fillet ( T-joint, lap &

Corner), Butt (Square & V); different position - 1F, 2F,3F,4F, 1G, 2G, 3G, 4G] 1.3.38 - 1.3.41

9 Perform welding in different types of MS pipe joints by Gas welding (OAW). [Different

types of MS pipe joints - Butt, Elbow, T-joint, angle (45) joint, flange joint] 1.3.42-1.3.45

10 Set the SMAW machine and perform different type of joints on MS in different

position observing standard procedure. [different types of joints Fillet ( T-joint, lap &

Corner), Butt (Square & V); different position - 1F, 2F,3F, 4F, 1G, 2G, 3G, 4G] 1.3.46 - 1.3.49

11 Set the SMAW machine and perform welding in different types of MS pipe joints by

SMAW. [Different types of MS pipe joints - Butt, Elbow, T-joint, angle (45 ) joint,

flange joint] 1.3.50 - 1.3.51

12 Choose appropriate welding process and perform joining of different types of metals

and check its correctness. [appropriate welding process - OAW, SMAW; Different

metal - SS, CI, Brass, Aluminium] 1.3.52 - 1.3.54

13 Choose appropriate welding process and perform joining of different types of metals

and check its correctness. [appropriate welding process - OAW, SMAW; Different

metal - SS, CI, Brass, Aluminium] Demonstrate arc gauging operation to rectify the

weld joints. 1.3.55 - 1.3.57

14 Choose appropriate welding process and perform joining of different types of metals

and check its correctness. [appropriate welding process - OAW, SMAW; Different

metal - SS, CI, Brass, Aluminium] 1.3.58 - 1.3.59

15 Test welded joints by different methods of testing. [different methods of testing- Dye

penetration test, Magnetic particle test, Nick break test, Free band test, Fillet fracture

test] 1.3.60 - 1.4.64

16 Set GMAW machine and perform welding in different types of joints on MS sheet/plate

by GMAW in various positions by dip mode of metal transfer. [different types of

joints- Fillet (T-joint, lap, Corner), Butt (Square & V); various positions- 1F, 2F, 3F,4F,

1G, 2G, 3G] 1.5.65 - 1.6.85

17 Set the GTAW machine and perform welding by GTAW in different types of joints on

different metals in different position and check correctness of the weld. [different types

of joints- Fillet ( T-joint, lap, Corner), Butt (Square & V) ; different metals- Aluminium,

Stainless Steel; different position- 1F & 1G] 1.6.86 - 1.6.91

18 Perform Aluminium & MS pipe joint by GTAW in flat position. 1.6.92

19 Perform Aluminium & MS pipe joint by GTAW in flat position. Set the Plasma Arc

cutting machine and cut ferrous & non-ferrous metals. 1.6.93 - 1.6.94

20 Set the resistance spot welding machine and join MS & SS sheet 1.6.95 - 161.96

21 Perform joining of different similar and dissimilar metals by brazing operation as per

standard procedure. [different similar and dissimilar metals- Copper, MS, SS] 1.6.97 - 1.7.100

22 Repair Cast Iron machine parts by selecting appropriate welding process.

[Appropriate welding process- OAW, SMAW]

Hard facing of alloy steel components / MS rod by using hard facing electrode. 1.7.101 - 1.7.104

(xii)