Page 14 - Fitter 2nd Year TT - Telugu

P. 14

properties and uses in bearings

such as phenolic, Teflon polyamide

(nylon). (06hrs.)

146. Preparation of drill gauges. (10 hrs.) The importance of keeping the work

147. File and fit straight and angular free from rust and corrosion. (06

surfaces internally. (13 hrs.) hrs.)

148. Identify different ferrous metals by

spark test (2 hrs.)

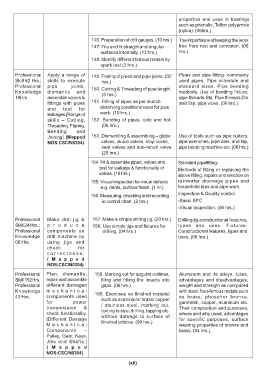

Professional Apply a range of 149. Flaring of pipes and pipe joints. (02 Pipes and pipe fitting- commonly

Skill 62 Hrs.; skills to execute hrs.) used pipes. Pipe schedule and

Professional pipe joints, 150. Cutting & Threading of pipe length. standard sizes. Pipe bending

Knowledge dismantle and (3 hrs.) methods. Use of bending fixture,

18Hrs assemble valves & pipe threads-Std. Pipe threads Die

fittings with pipes 151. Fitting of pipes as per sketch and Tap, pipe vices. (06 hrs.)

and test for observing conditions used for pipe

leakages.[Range of work. (10 hrs.)

skills – Cutting, 152. Bending of pipes- cold and hot.

Threading, Flaring, (06 hrs.)

Bending and

Joining] (Mapped 153. Dismantling & assembling – globe Use of tools such as pipe cutters,

NOS:CSC/N0304) valves, sluice valves, stop cocks, pipe wrenches, pipe dies, and tap,

seat valves and non-return valve. pipe bending machine etc. (06 hrs.)

(20 hrs.)

154. Fit & assemble pipes, valves and Standard pipefitting-

test for leakage & functionality of Methods of fitting or replacing the

valves. (18 hrs.) above fitting, repairs and erection on

155. Visual inspection for visual defects rainwater drainage pipes and

e.g. dents, surface finish. (1 hr.) household taps and pipe work.

156. Measuring, checking and recording Inspection & Quality control

in control chart. (2 hrs.) -Basic SPC

-Visual Inspection. (06 hrs.)

Professional Make drill jig & 157. Make a simple drilling jig. (20 hrs.) Drilling jig-constructional features,

Skill 24 Hrs.; produce 158. Use simple jigs and fixtures for types and uses. Fixtures-

Professional components on drilling. (04 hrs.) Constructional features, types and

Knowledge drill machine by uses. (06 hrs.)

06 Hrs. using jigs and

check for

correctness.

(Mapped

NOS:CSC/N0304)

Professional Plan, dismantle, 159. Marking out for angular outlines, Aluminum and its alloys. Uses,

Skill 152Hrs. repair and assemble filing and fitting the inserts into advantages and disadvantages,

Professional different damaged gaps. (06 hrs.) weight and strength as compared

Knowledge mechanical 160. Exercises on finished material with steel. Non-ferrous metals such

43 Hrs. components used such as aluminium/ brass/ copper as brass, phosphor bronze,

for power / stainless steel, marking out, gunmetal, copper, aluminum etc.

transmission & cutting to size, drilling, tapping etc. Their composition and purposes,

check functionality. without damage to surface of where and why used, advantages

[Different Damage finished articles. (09 hrs.) for specific purposes, surface

Mechanical wearing properties of bronze and

Components – brass. (04 hrs.)

Pulley, Gear, Keys,

Jibs and Shafts.]

(Mapped

NOS:CSC/N0304)

(xii)

(xii)