Page 11 - Fitter 2nd Year TT - Telugu

P. 11

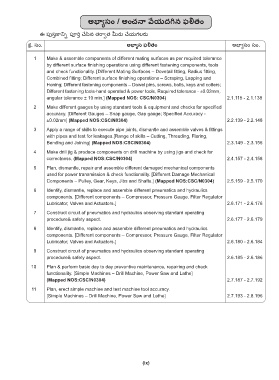

అభ్ాయాసం / అంచన్ఘ వైేయదగిన ఫల్త్ం

ఈ ప్ుస్తికాన్ై ప్ూరైితి చ్యస్్టన తరైా్వత మీర్ు చ్యయగలైర్ు

క్రా. స్ం. అభ్ాయాస ఫల్త్ం అభాయూస్ం స్ం.

1 Make & assemble components of different mating surfaces as per required tolerance

by different surface finishing operations using different fastening components, tools

and check functionality. [Different Mating Surfaces – Dovetail fitting, Radius fitting,

Combined fitting; Different surface finishing operations – Scraping, Lapping and

Honing; Different fastening components – Dowel pins, screws, bolts, keys and cotters;

Different fastening tools-hand operated & power tools, Required tolerance - ±0.02mm,

angular tolerance ± 10 min.] (Mapped NOS: CSC/N0304) 2.1.115 - 2.1.138

2 Make different gauges by using standard tools & equipment and checks for specified

accuracy. [Different Gauges – Snap gauge, Gap gauge; Specified Accuracy -

±0.02mm] (Mapped NOS:CSC/N0304) 2.2.139 - 2.2.148

3 Apply a range of skills to execute pipe joints, dismantle and assemble valves & fittings

with pipes and test for leakages.[Range of skills – Cutting, Threading, Flaring,

Bending and Joining] (Mapped NOS:CSC/N0304) 2.3.149 - 2.3.156

4 Make drill jig & produce components on drill machine by using jigs and check for

correctness. (Mapped NOS:CSC/N0304) 2.4.157 - 2.4.158

5 Plan, dismantle, repair and assemble different damaged mechanical components

used for power transmission & check functionality. [Different Damage Mechanical

Components – Pulley, Gear, Keys, Jibs and Shafts.] (Mapped NOS:CSC/N0304) 2.5.159 - 2.5.170

6 Identify, dismantle, replace and assemble different pneumatics and hydraulics

components. [Different components – Compressor, Pressure Gauge, Filter Regulator

Lubricator, Valves and Actuators.] 2.6.171 - 2.6.176

7 Construct circuit of pneumatics and hydraulics observing standard operating

procedure& safety aspect. 2.6.177 - 2.6.179

8 Identify, dismantle, replace and assemble different pneumatics and hydraulics

components. [Different components – Compressor, Pressure Gauge, Filter Regulator

Lubricator, Valves and Actuators.] 2.6.180 - 2.6.184

9 Construct circuit of pneumatics and hydraulics observing standard operating

procedure& safety aspect. 2.6.185 - 2.6.186

10 Plan & perform basic day to day preventive maintenance, repairing and check

functionality. [Simple Machines – Drill Machine, Power Saw and Lathe]

(Mapped NOS:CSC/N0304) 2.7.187 - 2.7.192

11 Plan, erect simple machine and test machine tool accuracy.

[Simple Machines – Drill Machine, Power Saw and Lathe] 2.7.193 - 2.8.196

(ix)