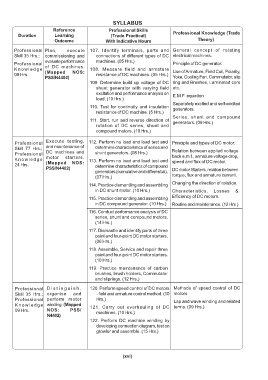

Page 18 - Electrician - 2nd Year TP

P. 18

SYLLABUS

Reference Professional Skills

Duration Learning (Trade Practical) Professional Knowledge (Trade

Outcome With Indicative Hours Theory)

Professional Plan, execute 107. Identify terminals, parts and General concept of rotating

Skill 35 Hrs.; commissioning and connections of different types of DC electrical machines.

evaluate performance machines. (05 Hrs.)

Professional of DC machines. Principle of DC generator.

Knowledge (Mapped NOS: 108. Measure field and armature Use of Armature, Field Coil, Polarity,

09 Hrs. resistance of DC machines. (05 Hrs.)

PSS/N4402) Yoke, Cooling Fan, Commutator, slip

109. Determine build up voltage of DC ring and Brushes, Laminated core

shunt generator with varying field etc.

excitation and performance analysis on E.M.F. equation

load. (10 Hrs.)

Separately excited and self-excited

110. Test for continuity and insulation generators.

resistance of DC machine. (5 Hrs.)

Series, shunt and compound

111. Start, run and reverse direction of generators. (09 Hrs.)

rotation of DC series, shunt and

compound motors. (10 Hrs.)

Professional Execute testing, 112. Perform no load and load test and Principle and types of DC motor.

Skill 77 Hrs.; and maintenance of determine characteristics of series and Relation between applied voltage

Professional DC machines and shunt generators. (08 Hrs.) back e.m.f., armature voltage drop,

Knowledge motor starters. 113. Perform no load and load test and speed and flux of DC motor.

24 Hrs. (Mapped NOS: determine characteristics of compound

PSS/N4402) DC motor Starters, relation between

generators (cumulative and differential).

(07 Hrs.) torque, flux and armature current.

114. Practice dismantling and assembling Changing the direction of rotation.

in DC shunt motor. (10 Hrs.) Characteristics, Losses &

Efficiency of DC motors.

115. Practice dismantling and assembling

in DC compound generator. (10 Hrs.) Routine and maintenance. (12 Hrs.)

116. Conduct performance analysis of DC

series, shunt and compound motors.

(14 Hrs.)

117. Dismantle and identify parts of three

point and four-point DC motor starters.

(06 Hrs.)

118. Assemble, Service and repair three

point and four-point DC motor starters.

(10 Hrs.)

119. Practice maintenance of carbon

brushes, brush holders, Commutator

and sliprings. (12 Hrs.)

Professional Distinguish, 120. Perform speed control of DC motors Methods of speed control of DC

Skill 35 Hrs.; organise and - field and armature control method. (10 motors.

Professional perform motor Hrs.) Lap and wave winding and related

Knowledge winding. (Mapped 121. Carry out overhauling of DC terms. (09 Hrs.)

09 Hrs. NOS: PSS/ machines. (10 Hrs.)

N4402)

122. Perform DC machine winding by

developing connection diagram, test on

growler and assemble. (15 Hrs.)

(xvi)