Page 18 - Welder (W&I)- TT - Telugu

P. 18

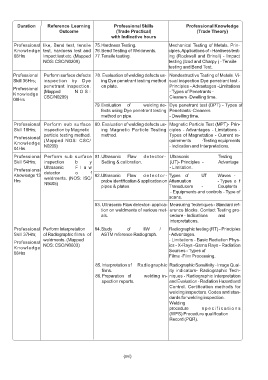

Duration Reference Learning Professional Skills Professional Knowledge

Outcome (Trade Practical) (Trade Theory)

with Indicative hours

Professional like, Bend test, tensile 75.Hardness Testing. Mechanical Testing of Metals. Prin-

Knowledge test, hardness test and 76.Bend Testing of Weldments. ciples, Applications of - Hardness test-

08Hrs Impact test etc. (Mapped 77.Tensile testing. ing (Rockwell and Brinell) - Impact

NOS: CSC/N0209) testing (Izod and Charpy ) - Tensile

testing and Bend Test.

Professional Perform surface defects 78. Evaluation of welding defects us- Nondestructive Testing of Metals. Vi-

Skill 36Hrs; inspection by Dye ing Dye penetrant testing method sual inspection Dye penetrant test -

penetrant Inspection. on plate. Principles - Advantages -Limitations

Professional (Mapped NOS: - Types of Penetrants -

Knowledge CSC/N0209) Cleaners -Dwelling time.

08Hrs

79.Evaluation of welding de- Dye penetrant test (DPT) - Types of

fects using Dye penetrant testing Penetrants -Cleaners

method on pipe. - Dwelling time.

Professional Perform sub surface 80. Evaluation of welding defects us- Magnetic Particle Test (MPT)- Prin-

Skill 18Hrs; inspection by Magnetic ing Magnetic Particle Testing ciples - Advantages - Limitations -

particle testing method. method. Types of Magnetation - Current re-

Professional

Knowledge (Mapped NOS: CSC/ quirements -Testing equipments

04Hrs N0209) - Indication and Interpretations.

Professional Perform sub surface 81.Ultrasonic Flaw detector- Ultrasonic Testing

Skill 54Hrs; inspection b y Setting & calibration. (UT)- Principles - Advantage

Ultrasonic Flaw - Limitation.

Professional detector o f

Knowledge 13 weldments. (NOS: ISC/ 82.Ultrasonic Flaw detector- Types of UT Waves -

Hrs probe identification & application on Attenuation - Types o f

N9405)

pipes & plates. Transducers - Couplants

- Equipments and controls - Type of

scans.

83. Ultrasonic Flaw detector- applica- Measuring Techniques - Standard ref-

tion on weldments of various met- erence blocks. Contact Testing pro-

als. cedure - Indications and

interpretations.

Professional Perform Interpretation 84.Study of IIW / Radiographic testing (RT) - Principles

Skill 37Hrs; of Radiographic films of ASTM reference Radiograph. - Advantages.

weldments. (Mapped - Limitations - Basic Radiation Phys-

Professional

Knowledge NOS: CSC/N0603) ics - X-Rays -Gama Rays - Radiation

08Hrs Sources - Types of

Films -Film Processing.

85.Interpretation of Radiographic Radiographic Sensitivity - Image Qual-

films. ity indicators- Radiographic Tech-

86.Preparation of welding in- niques - Radiographic Interpretation

spection reports. and Evaluation - Radiation Hazard and

Control. Certification methods for

welding inspectors. Codes and stan-

dards for welding inspection.

Welding

procedure specifications

(WPS) Procedure qualification

Record (PQR).

(xvi)