Page 17 - Welder (W&I)- TT - Telugu

P. 17

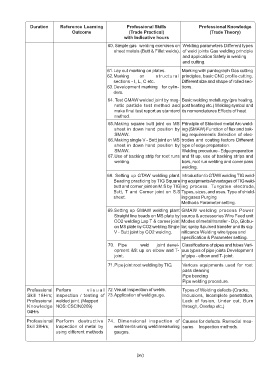

Duration Reference Learning Professional Skills Professional Knowledge

Outcome (Trade Practical) (Trade Theory)

with Indicative hours

60. Simple gas welding exercises on Welding parameters Different types

sheet metals (Butt & Fillet welds). of weld joints Gas welding principle

and application Safety in welding

and cutting.

61.Lay out marking on plates. Marking with pantograph Gas cutting

62.Marking on structural principles, basic CNC profile cutting.

sections - I, L, C etc. Different size and shape of rolled sec-

63.Development marking for cylin- tions.

ders.

64. Test GMAW welded joint by mag- Basic welding metallurgy (pre heating,

netic particle test method and post heating etc.) Welding symbol and

make final test report as standard its nomenclatures Effects of heat.

method.

65.Making square butt joint on MS Principle of Shielded metal Arc weld-

sheet in down hand position by ing (SMAW) Function of flux and bak-

SMAW. ing requirements Selection of elec-

66.Making single V - Butt joint on MS trodes and coating factors Different

sheet in down hand position by type of edge preparation.

SMAW. Welding procedure - Edge preparation

67.Use of backing strip for root runs and fit up, use of backing strips and

welding. bars, root run welding and cover pass

welding.

68. Setting up GTAW welding plant. Introduction to GTAW welding TIG weld-

Beading practicing by TIG Square ing equipments Advantages of TIG weld-

butt and corner joint on M.S by TIG ing process. Tungsten electrode,

Butt, T and Corner joint on S.S Types, sizes, and uses. Type of shield-

sheet. ing gases Purging

Methods Parameter setting.

69.Setting up GMAW welding plant GMAW welding process Power

Straight line beads on MS plate by source & accessories Wire Feed unit

CO2 welding Lap T & corner joint Modes of metal transfer - Dip, Globu-

on MS plate by CO2 welding Single lar, spray &pulsed transfer and its sig-

V - Butt joint by CO2 welding. nificance Welding wire types and

specification & Parameter setting.

70. Pipe weld joint devel- Classifications of pipes and tubes Vari-

opment &fit up on elbow and T- ous types of pipe joints Development

joint. of pipe - elbow and T- joint.

71.Pipe joint root welding by TIG. Various equipments used for root

pass cleaning

Pipe bending

Pipe welding procedure.

Professional Perform visual 72.Visual Inspection of welds. Types of Welding defects (Cracks,

Skill 18Hrs; inspection / testing of 73.Application of weld gauge. Inclusions, Incomplete penetration,

Professional welded joint. (Mapped Lack of fusion, Under cut, Burn

Knowledge NOS: CSC/N0209) through, Overlap etc.)

04Hrs

Professional Perform destructive 74. Dimensional inspection of Causes for defects. Remedial mea-

Skill 39Hrs; Inspection of metal by weldments using weld measuring sures Inspection methods.

using different methods gauges.

(xv)