Page 16 - Welder (W&I)- TT - Telugu

P. 16

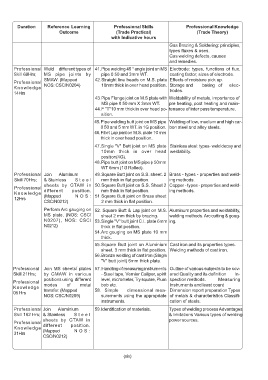

Duration Reference Learning Professional Skills Professional Knowledge

Outcome (Trade Practical) (Trade Theory)

with Indicative hours

Gas Brazing & Soldering: principles,

types fluxes & uses.

Gas welding defects, causes

and remedies.

Professional Weld different types of 41.Pipe welding 45 ° angle joint on MS Electrode: types, functions of flux,

Skill 69Hrs; MS pipe joints by pipe 0 50 and 3mm WT. coating factor, sizes of electrode.

SMAW. (Mapped 42.Straight line beads on M.S. plate Effects of moisture pick up.

Professional NOS: CSC/N0204) 10mm thick in over head position. Storage and baking of elec-

Knowledge trodes.

14Hrs

43.Pipe Flange joint on M.S plate with Weldability of metals, importance of

MS pipe 0 50 mm X 3mm WT. pre heating, post heating and main-

44.F "T"10 mm thick in over head po- tenance of inter pass temperature.

sition.

45.Pipe welding butt joint on MS pipe Welding of low, medium and high car-

0 50 and 5 mm WT. in 1G position. bon steel and alloy steels.

46.Fillet Lap joint on M.S. plate 10 mm

thick in over head position.

47.Single "V" Butt joint on MS plate Stainless steel: types- weld decay and

10mm thick in over head weldability.

position(4G).

48.Pipe butt joint on MS pipe φ 50mm

WT 6mm (1G Rolled).

Professional Join Aluminum 49.Square Butt joint on S.S. sheet. 2 Brass - types - properties and weld-

Skill 70Hrs; & Stainless S teel mm thick in flat position. ing methods.

sheets by GTAW in 50.Square Butt joint on S.S. Sheet 2 Copper - types - properties and weld-

Professional

Knowledge different position. mm thick in flat position. ing methods.

12Hrs (Mapped NOS: 51.Square Butt joint on Brass sheet

CSC/N0212) 2 mm thick in flat position.

Perform Arc gauging on 52. Square Butt & Lap joint on M.S. Aluminum properties and weldability,

MS plate. (NOS: CSC/ sheet 2 mm thick by brazing. welding methods. Arc cutting & goug-

N0207), NOS: CSC/ 53.Single "V" butt joint C.I. plate 6mm ing.

N0212) thick in flat position.

54.Arc gouging on MS plate 10 mm

thick.

55.Square Butt joint on Aluminium Cast iron and its properties types.

sheet. 3 mm thick in flat position. Welding methods of cast iron.

56.Bronze welding of cast iron (Single

"V" butt joint) 6mm thick plate.

Professional Join MS sheets/ plates 57. Handling of measuring instruments Outline of various subjects to be cov-

Skill 21Hrs; by GMAW in various - Steel tape, Vernier Caliper, spirit ered Quality and its definition In-

positions using different level, micrometer, Try square, Plum spection methods. Measuring

Professional

Knowledge modes of metal bob etc. Instruments and least count

05 Hrs transfer. (Mapped 58. Simple dimensional mea- Dimension report preparation Types

NOS: CSC/N0209) surements using the appropriate of metals & characteristics Classifi-

instruments. cation of steels.

Professional Join Aluminium 59.Identification of materials. Types of welding process Advantages

Skill 162 Hrs; & Stainless S teel & limitations Various types of welding

sheets by GTAW in power sources.

Professional different position.

Knowledge (Mapped NOS:

31Hrs

CSC/N0212)

(xiv)