Page 14 - Welder (W&I)- TT - Telugu

P. 14

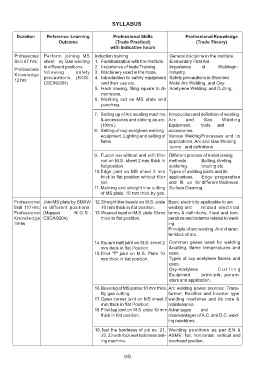

SYLLABUS

Duration Reference Learning Professional Skills Professional Knowledge

Outcome (Trade Practical) (Trade Theory)

with Indicative hours

Professional Perform joining MS Induction training: General discipline in the Institute.

Skill 67 hrs; sheet by Gas welding 1. Familiarization with the Institute. Elementary First Aid.

in different positions 2. Importance of trade Training. Importance of Weldingin

Professional following safety 3. Machinery used in the trade. Industry.

Knowledge precautions. (NOS: 4. Introduction to safety equipment Safety precautions in Shielded

12 hrs

CSC/N0204) and their use etc. Metal Arc Welding, and Oxy-

5. Hack sawing, filing square to di- Acetylene Welding and Cutting.

mensions.

6. Marking out on MS plate and

punching.

7. Setting up of Arc welding machine Introduction and definition of welding.

& accessories and striking an arc. Arc and Gas Welding

(10hrs.) Equipment, tools and

8. Setting of oxy-acetylene welding accessories.

equipment, Lighting and setting of Various WeldingProcesses and its

flame. applications. Arc and Gas Welding

terms and definitions.

9. Fusion run without and with filler Different process of metal joining

rod on M.S. sheet 2 mm thick in methods: Bolting, riveting,

flat position. soldering, brazing etc.

10.Edge joint on MS sheet 2 mm Types of welding joints and its

thick in flat position without filler applications. Edge preparation

rod. and fit up for different thickness.

11.Marking and straight line cutting Surface Cleaning.

of MS plate. 10 mm thick by gas.

Professional Join MS plate by SMAW 12.Straight line beads on M.S. plate Basic electricity applicable to arc

Skill 117Hrs; in different positions. 10 mm thick in flat position. welding and related electrical

Professional (Mapped NOS: 13.Weaved bead on M.S. plate 10mm terms & definitions. Heat and tem-

Knowledge CSC/N0204) thick in flat position. perature and its terms related to weld-

19Hrs ing.

Principle of arc welding. And charac-

teristics of arc.

14.Square butt joint on M.S. sheet 2 Common gases used for welding

mm thick in flat Position. &cutting, flame temperatures and

15.Fillet "T" joint on M.S. Plate 10 uses.

mm thick in flat position. Types of oxy-acetylene flames and

uses.

Oxy-Acetylene Cutting

Equipment principle, param-

eters and application.

16.Beveling of MS plates 10 mm thick. Arc welding power sources: Trans-

By gas cutting. former, Rectifier and Inverter type

17.Open corner joint on MS sheet 2 welding machines and its care &

mm thick in flat Position. maintenance.

18.Fillet lap joint on M.S. plate 10 mm Advantages and

thick in flat position. disadvantages of A.C. and D.C. weld-

ing machines.

19.Test the hardness of job no. 21, Welding positions as per EN &

22, 23 with rock well hardness test- ASME: flat, horizontal, vertical and

ing machine. overhead position.

(xii)