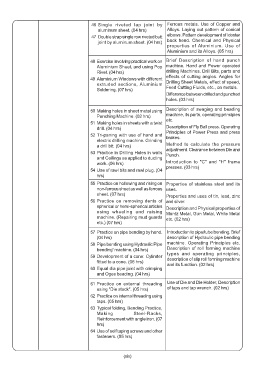

Page 16 - Sheet Metal Worker -TT- TELUGU

P. 16

46 Single riveted lap joint by Ferrous metals. Use of Copper and

aluminum sheet. (04 hrs) Alloys. Laying out pattern of conical

47 Double strap single row riveted butt elbows. Pattern development of lobster

joint by aluminum sheet. (04 hrs) back bend. Chemical and Physical

properties of Aluminium. Use of

Aluminium and its Alloys. (05 hrs)

48 Exercise involving practical work on Brief Description of hand punch

Aluminium Sheet, and using Pop machine. Hand and Power operated

Rivet. (04 hrs) drilling Machines. Drill Bits, parts and

effects of cutting angles. Angles for

49 Aluminium Windows with different

extruded sections, Aluminium Drilling Sheet Metals, effect of speed,

Soldering. (07 hrs) Feed Cutting Fluids, etc., on metals.

Difference between drilled and punched

holes. (03 hrs)

50 Making holes in sheet metal using Description of swaging and beading

Punching Machine. (02 hrs) machine, its parts, operating principles

etc.

51 Making holes in sheets with a twist

drill. (04 hrs) Description of Fly Ball press. Operating

Principles of Power Press and press

52 Tri-paning with use of hand and brakes.

electric drilling machine. Grinding

a drill bit. (04 hrs) Method to calculate the pressure

adjustment. Clearance between Die and

53 Practice in Drilling Holes in walls Punch.

and Ceilings as applied to ducting

work. (06 hrs) Introduction to "C" and "H" frame

54 Use of rawl bits and rawl plug. (04 presses. (03 hrs)

hrs)

55 Practice on hollowing and rising on Properties of stainless steel and its

non-ferrous sheet as well as ferrous uses.

sheet. (07 hrs) Properties and uses of tin, lead, zinc

56 Practice on removing dents of and silver.

spherical or hemi-spherical articles Description and Physical properties of

using wheeling and raising Muntz Metal, Gun Metal, White Metal

machine. (Repairing mud guards etc. (02 hrs)

etc.) (07 hrs)

57 Practice on pipe bending by hand. Introduction to pipe/tube bending. Brief

(04 hrs) description of Hydraulic pipe bending

58 Pipe bending using Hydraulic Pipe machine. Operating Principles etc.

bending' machine. (04 hrs) Description of roll forming machine

59 Development of a cone: Cylinder types and operating principles,

fitted to a cone. (06 hrs) description of slip roll forming machine

and its function. (02 hrs)

60 Equal dia pipe joint with crimping

and Ogee beading. (04 hrs)

61 Practice on external threading Use of Die and Die Holder, Description

using "Die stock". (05 hrs) of taps and tap wrench. (02 hrs)

62 Practice on internal threading using

taps. (05 hrs)

63 Typical folding, Bending Practice,

Making Steel-Racks,

Reinforcement with angle iron. (07

hrs)

64 Use of self taping screws and other

fasteners. (05 hrs)

(xiv)