Page 13 - Sheet Metal Worker -TT- TELUGU

P. 13

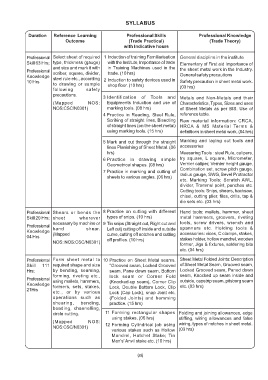

SYLLABUS

Duration Reference Learning Professional Skills Professional Knowledge

Outcome (Trade Practical) (Trade Theory)

with Indicative hours

Professional Select sheet of required 1 Induction of training Familiarisation General discipline in the institute

Skill 63 Hrs; type, thickness (gauge) with the Institute, Importance of trade Elementary of First aid Importance of

and size and mark it with in Training Machines used in the the sheet metal work in the Industry.

Professional scriber, square, divider, trade. (10 hrs)

Knowledge steel rule etc., according General safety precautions

10 Hrs 2 Induction to safety devices used in Safety precaution in sheet metal work.

to drawing or sample shop floor. (10 hrs) (03 hrs)

following safety

precautions.

3 Identification of Tools and Metals and Non-Metals and their

(Mapped NOS: Equipments Induction and use of Characteristics, Types, Sizes and uses

NOS:CSC/N0301) marking tools. (08 hrs) of Sheet Metals as per BIS. Use of

4 Practice in Reading, Steel Rule, reference table.

Scribing of straight lines, Bisecting Raw material information: CRCA,

of straight lines (on the sheet metal) HRCA & MS Material Terms &

using marking tools. (15 hrs) definitions in sheet metal work. (04 hrs)

5 Mark and cut through the straight Marking and laying out tools and

lines Planishing of Sheet Metal. (06 accessories

hrs) Measuring Tools : steel Rule, calipers,

6 Practice in drawing simple try square, L square, Micrometer,

Geometrical shapes. (08 hrs) Vernier caliper, Vernier height gauge,

7 Practice in marking and cutting of Combination set, screw pitch gauge,

sheets to various angles. (06 hrs) radius gauge, SWG, Bevel Protractor

etc. Marking Tools: Scratch AWL,

divider, Trammel point, punches etc.

Cutting tools: Snips, shears, hacksaw,

chisel, cutting plier, files, drills, tap &

die sets etc. (03 hrs)

Professional Shears or bends the 8 Practice on cutting with different Hand tools: mallets, hammer, sheet

Skill 20 Hrs; sheet wherever types of snips. (10 hrs) metal hammers, groovers, riveting

necessary by machine or 9 Tin snips (Straight cut, Right cut and tools, screw drivers, wrench and

Professional hand shear.

Knowledge (Mapped Left cut) cutting off inside and outside spanners etc. Holding tools &

04 Hrs curve, cutting off notches and cutting accessories: vices, C clamps, stakes,

stakes holder, hollow mandrel, wooden

NOS: NOS:CSC/N0301) off profiles. (10 hrs)

former, Jigs & fixtures, soldering bits

etc. (04 hrs)

Professional Form sheet metal to 10 Practice on Sheet Metal seams. Sheet Metal Folded Joints: Description

Skill 111 required shape and size "Grooved seam, Locked Grooved of Sheet Metal Seam, Grooved seam,

Hrs; by bending, seaming, seam, Pane down seam, Bottom Locked Grooved seam, Paned down

forming, riveting etc., lock seam or Corner Fold seam, Knocked up seam inside and

Professional using mallets, hammers, outside, capstrip seam, pitsburg seam

Knowledge formers, sets, stakes, (Knocked-up seam), Corner Clip etc. (03 hrs)

21Hrs Lock, Double Bottom Lock, Clip

etc., or by various Lock (Cap Lock), snap Joint etc.

operations such as (Folded Joints) and hemming

shearing, bending, practice. (15 hrs)

beading, channelling,

circle cutting. 11 Forming rectangular shapes Folding and joining allowances, edge

using stakes. (06 hrs) stiffing, wiring allowances and false

(Mapped NOS: wiring, types of notches in sheet metal.

NOS:CSC/N0301) 12 Forming Cylindrical job using

various stakes such as Hollow (03 hrs)

Mandrel, Hatchet Stake; Tin

Man's' Anvil stake etc. (10 hrs)

(xi)