Page 14 - Sheet Metal Worker -TT- TELUGU

P. 14

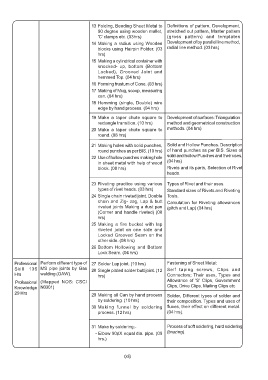

13 Folding, Bending Sheet Metal to Definitions of pattern, Development,

90 degree using wooden mallet, stretched out pattern, Master pattern

'C' clamps etc. (03hrs) (gross pattern) and templates

14 Making a radius using Wooden Development of by parallel line method,

blocks using Hairpin Folder. (03 radial line method. (03 hrs)

hrs)

15 Making a cylindrical container with

knocked- up, bottom (Bottom

Locked), Grooved Joint and

hemmed Top. (04 hrs)

16 Forming frustum of Cone. (03 hrs)

17 Making of Mug, scoop, measuring

can. (04 hrs)

18 Hemming (single, Double) wire

edge by hand process. (04 hrs)

19 Make a taper chute square to Development of surfaces: Triangulation

rectangle transition. (10 hrs) method and geometrical construction

20 Make a taper chute square to methods. (04 hrs)

round. (08 hrs)

21 Making holes with solid punches, Solid and Hollow Punches. Description

round punches as per BIS. (10 hrs) of hand punches as per BIS. Sizes of

22 Use of hollow punches making hole solid and hollow Punches and their uses.

in sheet metal with help of wood (04 hrs)

block. (08 hrs) Rivets and its parts, Selection of Rivet

heads.

23 Riveting practice using various Types of Rivet and their uses.

types of rivet heads. (03 hrs) Standard sizes of Rivets and Riveting

24 Single chain riveted joint. Double Tools.

chain and Zig- zag, Lap & butt Calculation for Riveting allowances

riveted joints Making a dust pan (pitch and Lap) (04 hrs)

(Corner and handle riveted) (08

hrs)

25 Making a fire bucket with lap

riveted joint on one side and

Locked Grooved Seam on the

other side. (08 hrs)

26 Bottom Hollowing and Bottom

Lock Seam. (04 hrs)

Professional Perform different type of 27 Solder Lap joint. (10 hrs) Fastening of Sheet Metal:

Skill 136 MS pipe joints by Gas 28 Single plated solder butt joint. (12 Self taping screws, Clips and

Hrs welding (OAW). hrs) Connectors; Their uses, Types and

Professional (Mapped NOS: CSC/ Allowance of 'S' Clips, Government

Knowledge N0301) Clips, Drive Clips, Mailing Clips etc

29 Hrs 29 Making oil Can by hand process Solder, Different types of solder and

by soldering. (10 hrs) their composition. Types and uses of

30 Making funnel by soldering fluxes, their effect on different metal.

process. (12 hrs) (04 hrs).

31 Make by soldering:- Process of soft soldering, hard soldering

- Elbow 90¢X equal dia. pipe. (09 (brazing).

hrs.)

(xii)