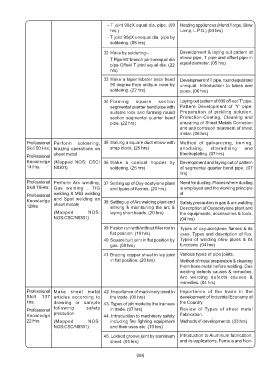

Page 15 - Sheet Metal Worker -TT- TELUGU

P. 15

- T joint 90¢X equal dia. pipe. (09 Heating appliances (Hand Forge, Blow

hrs.) Lamp, L.P.G.) (04 hrs)

- T joint 90¢X unequal dia. pipe by

soldering. (08 hrs)

32 Make by soldering:- Development & laying out pattern of

T Pipe 60°branch joint unequal dia elbow pipe, T pipe and offset pipe in

pipe Offset T joint equal dia. (22 equal diameter. (05 hrs)

hrs)

33 Make a taper lobster back bend Development of T pipe, round equal and

90 degree from oblique cone by unequal. Introduction to tubes and

soldering. (22 hrs) pipes. (06 hrs)

34 Forming square section Laying out pattern of 600 off-set 'T' pipe.

segmental quarter bend pipe with Pattern Development of 'Y' pipe.

suitable lock and forming round Preparation of pickling solution.

section segmental quarter bend Protection-Coating, Cleaning and

pipe. (22 hrs) preparing of Sheet Metals Corrosion

and anti corrosion treatment of sheet

metal. (06 hrs)

Professional Perform soldering, 35 Making a square duct elbow with Method of galvanizing, tinning,

Skill 50 Hrs; brazing operations on snap block. (25 hrs) anodising, sheradising and

Professional sheet metal. Electroplating. (07 hrs)

Knowledge (Mapped NOS: CSC/ 36 Make a conical hopper by Development and laying out of pattern

14 Hrs N0301) soldering. (25 hrs) of segmental quarter bend pipe. (07

hrs)

Professional Perform Arc welding, 37 Setting up of Oxy-acetylene plant Need for ducting. Places where ducting

Skill 78Hrs; Gas welding , TIG and types of flames. (20 hrs) is employed and the working principle

Professional welding & MIG welding of

Knowledge and Spot welding on 38 Setting up of Arc welding plant and Safety precaution in gas & arc welding

12Hrs sheet metals striking & maintaining the arc & Description of Oxyacetylene plant and

(Mapped NOS: laying short beads. (20 hrs) the equipments, accessories & tools.

NOS:CSC/N0301) (04 hrs)

39 Fusion run with/without filler rod in Types of oxy-acetylene flames & its

flat position. (10 hrs) uses. Types and description of flux.

40 Square butt joint in flat position by Types of welding blow pipes & its

gas. (08 hrs) functions. (04 hrs)

41 Brazing copper sheet in lap joint Various types of pipe joints.

in flat position. (20 hrs) Method of metal preparation & cleaning

them base metal before welding. Gas

welding defects causes & remedies.

Arc welding defects causes &

remedies. (04 hrs)

Professional Make sheet metal 42. Importance of machinery used in Importance of the trade in the

Skill 137 articles according to the trade. (05 hrs) development of Industrial Economy of

Hrs; drawing or sample 43. Types of job made by the trainees the Country.

Professional following safety in trade. (07 hrs) Review of Types of sheet metal

Knowledge precaution. 44. Introduction to machinery safety Fabrication.

22 Hrs (Mapped NOS: including fire fighting equipment Methods of developments. (03 hrs)

NOS:CSC/N0301) and their uses etc. (10 hrs)

45. Locked groove joint by aluminum Introduction to Aluminum fabrication,

sheet. (04 hrs) and its applications. Ferrous and Non-

(xiii)