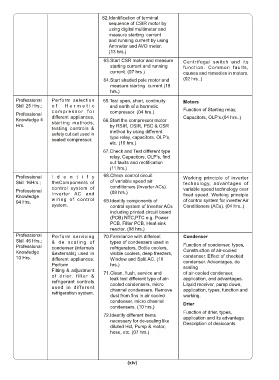

Page 16 - R&ACT 1st Year - TT- TELUGU

P. 16

62. Identification of terminal

sequence of CSIR motor by

using digital multimeter and

measure starting current

and running current by using

Ammeter and AVO meter.

(13 hrs.)

63. Start CSR motor and measure Centrifugal switch and its

starting current and running function. Common faults,

current. (07 hrs.) causes and remedies in motors.

64. Start shaded pole motor and (02 hrs..)

measure starting current (18

hrs.)

Professional Perform selection 65. Test open, short, continuity Motors

Skill 25 Hrs.; of Hermetic and earth of a hermetic

compressor for compressor. (04 hrs.) Function of Starting relay,

Professional different appliances,

Knowledge 4 starting methods, 66. Start the compressor motor Capacitors, OLP’s.(04 hrs..)

Hrs. by RSIR, CSIR, PSC & CSR

testing controls &

safety cut out used in method by using different

sealed compressor. type relay, capacitors, OLP’s,

etc. (10 hrs.)

67. Check and Test different type

relay, Capacitors, OLP’s, find

out faults and rectification

(11 hrs.)

Professional Identify 68. Check control circuit Working principle of inverter

Skill 16Hrs.; theComponents of of variable speed air technology, advantages of

control system of conditioners (Inverter ACs). variable speed technology over

Professional Inverter AC and (08 hrs.)

Knowledge wiring of control fixed speed. Working principle

04 Hrs. 69. Identify components of of control system for inverter Air

system. control system of Inverter ACs Conditioners (ACs). (04 hrs..)

including printed circuit board

(PCB) NTC,PTC e.g. Power

PCB, Filter PCB, Heat sink

reactor. (08 hrs.)

Professional Perform servicing 70. Familiarize with different Condenser

Skill 46 Hrs.; & de scaling of types of condensers used in

Professional condenser (internals refrigerators, Bottle coolers, Function of condenser, types,

Knowledge &externals) used in visible coolers, deep freezers, Construction of air-cooled

10 Hrs. different appliances. Window and Split AC. (10 condenser. Effect of chocked

Perform hrs.) condenser. Advantages, de

scaling

Fitting & adjustment 71. Clean, flush, service and of air-cooled condenser,

of drier, filter & leak test different type of air- application, and advantages.

refrigerant controls cooled condensers, micro Liquid receiver, pump down,

used in different channel condensers. Remove application, types, function and

refrigeration system.

dust from fins in air cooled working.

condenser, micro channel Drier

condensers. (10 hrs.)

Function of drier, types,

72. Identify different items application and its advantage.

necessary for de-scaling like Description of desiccants.

diluted Hcl, Pump & motor,

hose, etc. (07 hrs.)

(xiv)