Page 14 - R&ACT 1st Year - TT- TELUGU

P. 14

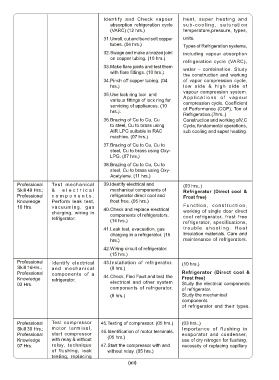

Identify and Check vapour heat, super heating and

absorption refrigeration cycle sub-cooling, saturation

(VARC) (12 hrs.) temperature,pressure, types,

31. Unroll, cut and bend soft copper units.

tubes. (04 hrs.) Types of Refrigeration systems,

32. Swage and make a brazed joint including vapour absorption

on copper tubing. (10 hrs.)

refrigeration cycle (VARC),

33. Make flare joints and test them water – combination. Study

with flare fittings. (10 hrs.)

the construction and working

34. Pinch off copper tubing. (04 of vapor compression cycle,

hrs.) low side & high side of

vapour compression system.

35. Use lock ring tool and

various fittings of lock ring for Applicat ions of vapour

servicing of appliances. (10 compression cycle. Coefficient

hrs.). of Performance (COP), Ton of

Refrigeration.(7hrs..)

36. Brazing of Cu to Cu, Cu Construction and working ofV.C

to steel, Cu to brass using Cycle, fundamental operations,

AIR LPG suitable in RAC sub cooling and super heating.

machine. (07 hrs.)

37. Brazing of Cu to Cu, Cu to

steel, Cu to brass using Oxy-

LPG. (07 hrs.)

38. Brazing of Cu to Cu, Cu to

steel, Cu to brass using Oxy-

Acetylene. (11 hrs.)

Professional Test mechanical 39. Identify electrical and (03 hrs..)

Skill 49 Hrs.; & elec t r ic al mechanical components of Refrigerator (Direct cool &

Professional co mp o n e n ts. refrigerator direct cool and Frost free)

Knowledge Perform leak test, frost free. (05 hrs.)

10 Hrs. vacuuming, gas 40. Check and replace electrical Function, construction,

charging, wiring in components of refrigerators. working of single door direct

refrigerator. (14 hrs.) cool refrigerator, frost free

refrigerator, specifications,

41. Leak test, evacuation, gas trouble shooting. Heat

charging in a refrigerator. (15 Insulation materials. Care and

hrs.) maintenance of refrigerators.

42. Wiring circuit of refrigerator.

(15 hrs.)

Professional Identify electrical 43. Installation of refrigerator. (10 hrs.)

Skill 16Hrs.; and mechanical (8 hrs.)

Professional components of a Refrigerator (Direct cool &

Knowledge refrigerator. 44. Check, Find Fault and test the Frost free)

03 Hrs. electrical and other system Study the electrical components

components of refrigerator. of refrigerator.

(8 hrs.) Study the mechanical

components

of refrigerator and their types.

Professional Test compressor 45. Testing of compressor. (05 hrs.) (03 hrs..)

Skill 30 Hrs.; motor terminal, 46. Identification of motor terminals. Importance of flushing in

Professional start compressor (05 hrs.) evaporator and condenser,

Knowledge with relay & without use of dry nitrogen for flushing,

07 Hrs. relay, technique 47. Start the compressor with and necessity of replacing capillary

of flushing, leak without relay. (05 hrs.)

testing, replacing

(xii)