Page 352 - Content.pmd

P. 352

ThXõe Øû\ (Puddling process) CkR RiÓLs £±V ÕiÓL[ôL

ùYhPlThÓ LhÓdL[ôL LhPlThÓ

©d CÚmûT Ñj§L¬jÕ úR²Úm×

ÁiÓm Tt±ûQdÏm ¨ûXdÏ

RVô¬dLlTÓ¡\Õ.

ùYlTlTÓjRlThÓ ÁiÓm EÚû[VôL

©d CÚmûT Ñj§L¬dÏm úTôÕ, UQp NjÕ EÚhPlTÓm.

ØÝYÕm ¿dLlTÓ¡\Õ. TôvTWØm

BvPu ùNVpØû\ (Aston process)

(phosphorus) ùTÚU[Ü ùY°úVt\lTÓ¡\Õ.

úUÛm LÓeL¬ (graphite) CÚm×Pu Juß CkR ùNVpØû\«p EÚdLlThP ©d

LXkRRôL (combined) Uôt\lTÓ¡\Õ. CÚm×m G@Ï L¯ÜLÞm JÚ ùTv³Uo

(Bessemer converter) Uôtß EûX«p

CkR ùNVpØû\Ls ThXõe EûXL°p

RVô¬dLlTÓ¡u\]. Ñj§L¬dLlThP

(puddling process) ùNVpTÓjRlTÓ¡u\].

EÚ¡V EúXôLm §\kR G¬YôÙ EûX«p

ThXõe YûL EûX (Puddling furnace) (open hearth furnace) CÚm× £XõdúLh ¨ûX«p

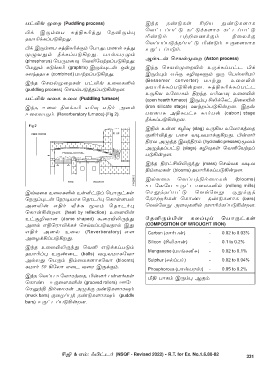

CkR EûX ¨XdL¬ G¬Ü G§o A]p (iron silicate stage) Ft\lTÓ¡u\]. CRu

EûXVôÏm. (Reverberatory furnace) (Fig 2). TV]ôL A§LThN LôoTu (cabon) stage

¿dLlTÓ¡u\].

C§p Es[ L¯Ü (slag) EÚ¡V EúXôLjûR

Ï°o®jÕ TûN Y¥YUôdÏ¡\Õ. ©u]o

§WY AÝjR CVk§Wm (hydraulic presses) êXm

AÝjRlThÓ (slags) L¯ÜLs ùY°úVt\l

TÓ¡u\].

CkR §Wh£«XõÚkÕ (mass) ùNqYL Y¥Y

§mûULs (blooms) RVô¬dLlTÓ¡u\].

CqYûL ùYlTj§mûULs (blooms)

EPú]úV EÚhPôûXL°p (rollong mills)

CqYûL EûXL°p EsÇhÓl ùTôÚhLs ùNÛjRlThÓ ùYqúYß ÏßdÏj

ùSÚl×Pu úSW¥VôL ùRôPo× ùLôs[Up úRôt\eLs ùLôiP RiÓL[ôL (bars)

A]Xõu G§o ÅfÑ êXm ùRôPo× ùYqúYß A[ÜL°p RVô¬dLlTÓ¡u\].

ùLôs¡u\]. (heat by reflection) Eû[«u

EhϯYô] (dome shaped) áûW«XõÚkÕ úR²Úm©u LXl×l ùTôÚhLs

A]p G§ùWôXõdLf ùNnVlTÓYRôp CÕ (COMPOSITION OF WROUGHT IRON)

G§o A]p EûX (Reverberatory) G] Carbon (LôoTu) - 0.02 to 0.03%

AûZd¡lTÓ¡\Õ.

Silicon (£XõLôu) - 0.1 to 0.2%

CkR EûX«XõÚkÕ ùY° GÓdLlTÓm

Manganese (UôeLÉÑ) - 0.02 to 0.1%

RVô¬l× EÚiûP (balls) Y¥YUôLúYô

ApXÕ ùTÚm §mûUL[ôLúYô (blooms) Sulphur (NplTo) - 0.02 to 0.04%

ÑUôo 50 ¡úXô GûP YûW CÚdÏm.

Phosphorous (TôvTWv) - 0.05 to 0.2%

CkR ùYlT EúXôLjûR, ©u]o Ts[eLs

Á§ TôLm CÚm× BÏm.

ùLôiP EÚû[L°u (grooved rollers) FúP

ùNÛj§ §mûULs AÝdÏ RiÓL[ôLÜm

(muck bars) ÏûZl×j RiÓL[ôLÜm (puddle

bars) EÚhPlTÓ¡u\].

£_õ & Gm: @©hPo (NSQF - Revised 2022) ------ R.T. for Ex. No.1.6.80-82

331