Page 355 - Content.pmd

P. 355

YôL]eL°s Ï°o®lTôu Es[LeLs

(radiator core) Utßm ¿oj §\l×d ÏZôn

B¡V] ùNnVl TVuTÓ¡\Õ. CÕ úUÛm

YôÙl Tt±ûQl× êXm L¥]l Tt\ô£Pp

Utßm TtÈÓ ùNnRp B¡V] ùNnVl

TVuTÓ¡\Õ. ©jRû[«u EÚÏ ¨ûX 880

o

XõÚkÕ 930 CYûW CÚdÏm.

TpúYß LXl× ®¡ReL°p ©jRû[Ls

ùNnVlThÓ, TpúYß ETúVôLeLÞdÏ

TVuTÓjRlTÓ¡u\].

ùYiLXm (Bronze): ùYiLXm GuTÕ

A¥lTûP«p ùNm×m DVØm LXkR LXl×

EúXôLm BÏm. £X R²lThP

ùNm©u LXl× EúXôLeLs (Copper alloys)

ÏQeLÞdLôL £X NUVm ÕjRSôLØm

©jRû[ (Brass): CÕ ùNm×m ÕjRSôLØm CjÕPu úNodLlTÓ¡\Õ. CRu ¨\m

LXkR EúXôLm BÏm. £XYûL £Ll©XõÚkÕ UgNs YûW CÚdÏm.

©jRû[LÞdÏ £±R[Ü LôÃVm ApXÕ ùYiLXj§u EÚϨûX 1005 C BÏm. CÕ

o

DVm úNodLlTÓ¡u\]. ©jRû[«u ¨\m ©jRû[ûV ®Pd L¥]Uô]RôÏm. CÕ

ARu LXl× EúXôLeLû[l ùTôÚjÕ áWô] ùYhÓd LÚ®Ls êXm G°RôL

CÚdÏm. CRu ¨\m UgNs, C[UgNs CVk§W®û] ùNnVlTÓm. EÚYôÏm

ApXÕ ¡hPjRhP ùYiûUVôL CÚdÏm. ©£oLs ùTô¥ Y¥Ym ùLôiPûY. £X

CRû] G°RôL CVk§W CûZl× £\l× ùYiLX LXl× EúXôLeLs TtÈÓ

ùNnVXôm. ©jRû[Ùm A¬l× G§ol×j (brazing) Lm©L[ôL TVuTÓ¡u\]. TpúYß

RuûU ùLôiPÕ. LXl× ®¡ReL°p TpúYß TVuTôÓLÞdÏ

©jRû[ ùTÚmTôÛm úUôhPôo ùYiLXm ¡ûPdÏm.

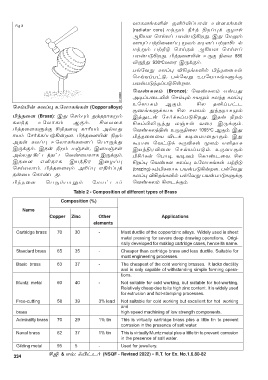

Table 2 - Composition of different types of Brass

Composition (%)

Name

Copper Zinc Other Applications

elements

Cartridge brass 70 30 - Most ductile of the copper/zinc alloys. Widely used in sheet

metal pressing for severe deep drawing operations. Origi-

nally developed for making cartridge cases, hence its name.

Standard brass 65 35 - Cheaper than cartridge brass and less ductile. Suitable for

most engineering processes.

Basic brass 63 37 - The cheapest of the cold working brasses. It lacks ductility

and is only capable of withstanding simple forming opera-

tions.

Muntz metal 60 40 - Not suitable for cold working, but suitable for hot-working.

Relatively cheap due to its high zinc content. It is widely used

for extrusion and hot-stamping processes.

Free-cutting 58 39 3% lead Not suitable for cold working but excellent for hot working

and

brass high speed machining of low strength components.

Admirality brass 70 29 1% tin This is virtually cartridge brass plus a little tin to prevent

corrosion in the presence of salt water.

Naval brass 62 37 1% tin This is virtually Muntz metal plus a little tin to prevent corrosion

in the presence of salt water.

Gilding metal 95 5 - Used for jewellery.

£_õ & Gm: @©hPo (NSQF - Revised 2022) ------ R.T. for Ex. No.1.6.80-82

334