Page 356 - Content.pmd

P. 356

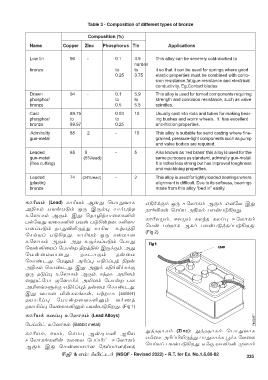

Table 3 - Composition of different types of bronze

Composition (%)

Name Copper Zinc Phosphorus Tin Applications

Low tin 96 - 0.1 3.9 This alloy can be severely cold-worked to

harden

bronze to to it so that it can be used for springs where good

0.25 3.75 elastic properties must be combined with corro-

sion resistance,fatigue-resistance and electrical

conductivity. Eg.Contact blades

Drawn 94 - 0.1 5.9 This alloy is used for turned components requiring

phosphor/ to to strength and corrosion resistance, such as valve

bronze 0.5 5.5 spindles.

Cast 89.75 0.03 10 Usually cast into rods and tubes for making bear-

phosphor/ to to ing bushes and worm wheels. It has excellent

bronze 89.97 0.25 anti-friction properties.

Admirality 88 2 - 10 This alloy is suitable for sand casting where fine-

gun-metal grained, pressure-tight components such as pump

and valve bodies are required.

Leaded 85 5 - 5 Also known as ‘red brass’ this alloy is used for the

gun-metal (5%lead) same purposes as standard, admiralty gun-metal.

(free cutting) It is rather less strong but has improved toughness

and machining properties.

Leaded 74 (24%lead) - 2 This alloy is used for lightly loaded bearings where

(plastic) alignment is difficult. Due to its softness, bearings

bronze made from this alloy “bed in” easily.

LôÃVm (Lead) LôÃVm B]Õ ùTôÕYôL G§odÏm JÚ EúXôLm BÏm. G]úY CÕ

A§Lm TVuTÓm JÚ CÚm× NôoTt\ Rôe¡Ls ùNnV A§Lm TVuTÓ¡\Õ.

EúXôLm BÏm. CÕ ùRô¯tNôûXL°p

LôÃVØm, DVØm LXkR LXl× EúXôLm

TpúYß YûLL°p TVu TÓ¡u\]. LXõ]ô

ùUu Tt\ôL BLl TVuTÓjRlTÓ¡\Õ.

G]lTÓm RôÕ®XõÚkÕ Lô¬V EtTj§

ùNnVl TÓ¡\Õ. Lô¬Vm JÚ L]Uô] (Fig 2)

EúXôLm BÏm. AÕ EÚdLlTÓm úTôÕ

ùYs°ûVl úTôu\ ¨\j§p CÚdÏm. AÕ

ùUuûUVô]Õ. RLPôÏm RuûU

ùLôiPÕ. úUÛm A¬l× G§ol×j §\u

A§Lm ùLôiPÕ. CÕ Aàd L§oÅfÑdÏ

JÚ RÓl× EúXôLm BÏm. LkRL AªXm

ûahúWô Ïú[ô¬d AªXm úTôu\ TX

AªXeLÞdÏ G§ol×j RuûU ùLôiPÕ.

CÕ YôL] ªuLXeLs, Tt\ôÑ (solder)

RVô¬l× úTôu\ûYL°Ûm YoQj

RVô¬l× úYûXL°Ûm TVuTÓ¡\Õ. (Fig 1)

LôÃVd LXl× EúXôLm (Lead Alloys)

úTl©h EúXôLm (Babbit metal)

ÕjRSôLm (Zinc): ÕjRSôLm ùTôÕYôL

LôÃVm, DVm, ùNm× Bu¥U² B¡V

G@ûL A¬l©XõÚkÕ TôÕLôdL éfÑ úYûX

EúXôLeL°u LXûY úTl©h EúXôLm

ùNnVl TVuTÓ¡\Õ. G@Ï Yô°Ls ØXôm

BÏm. CÕ ùUuûUVô] úRnUô]jûR

£_õ & Gm: @©hPo (NSQF - Revised 2022) ------ R.T. for Ex. No.1.6.80-82

335