Page 17 - MMV 1st Year - TT - Telugu

P. 17

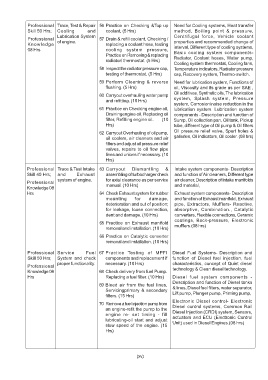

Professional Trace, Test & Repair 56 Practice on Checking &Top up Need for Cooling systems, Heat transfer

Skill 50 Hrs; Cooling and coolant, (5 Hrs) method, Boiling point & pressure,

Lubrication System Centrifugal force, Vehicle coolant

Professional of engine. 57 Drain & refill coolant, Checking / properties and recommended change of

Knowledge replacing a coolant hose, testing interval, Different type of cooling systems,

08 Hrs cooling system pressure, Basic cooling system components-

Practice on Removing & replacing Radiator, Coolant hoses, Water pump,

radiator/ thermostat. (5 Hrs)

Cooling system thermostat, Cooling fans,

58 Inspect the radiator pressure cap, Temperature indicators, Radiator pressure

testing of thermostat. (5 Hrs) cap, Recovery system, Thermo-switch.

59 Perform Cleaning & reverse Need for lubrication system, Functions of

flushing. (5 Hrs) oil, Viscosity and its grade as per SAE ,

60 Carryout overhauling water pump Oil additives, Synthetic oils, The lubrication

and refitting. (10 Hrs) system, Splash system, Pressure

system, Corrosion/noise reduction in the

61 Practice on Checking engine oil, lubrication system. Lubrication system

Drainingengine oil, Replacing oil components - Description and function of

filter, Refilling engine oil. (10 Sump, Oil collection pan, Oil tank, Pickup

Hrs) tube, different type of Oil pump & Oil filters

62 Carryout Overhauling of oil pump, Oil pressure relief valve, Spurt holes &

oil coolers, air cleaners and air galleries, Oil indicators, Oil cooler. (08 hrs)

filters and adjust oil pressure relief

valves, repairs to oil flow pipe

lines and unions if necessary. (10

Hrs)

Professional Trace & Test Intake 63 Carryout Dismantling & Intake system components- Description

Skill 40 Hrs; and Exhaust assembling of turbocharger check and function of Air cleaners, Different type

system of engine. for axial clearance as per service air cleaner, Description of Intake manifolds

Professional manual. (10 Hrs) and material,

Knowledge 08

Hrs 64 Check Exhaust system for rubber Exhaust system components- Description

mounting for damage, and function of Exhaust manifold, Exhaust

deterioration and out of position; pipe, Extractors, Mufflers- Reactive,

for leakage, loose connection, absorptive, Combination., Catalytic

dent and damage. (10 Hrs) converters, Flexible connections, Ceramic

coatings, Back-pressure, Electronic

65 Practice on Exhaust manifold

removal and installation. (10 Hrs) mufflers.(08 hrs)

66 Practice on Catalytic converter

removal and installation. (10 Hrs)

Professional Service Fuel 67 Practice Testing of MPFI Diesel Fuel Systems- Description and

Skill 50 Hrs; System and check components and replacement if function of Diesel fuel injection, fuel

proper functionality. necessary. (10 Hrs) characteristics, concept of Quiet diesel

Professional technology & Clean diesel technology.

Knowledge 08 68 Check delivery from fuel Pump.

Hrs Replacing a fuel filter. (10 Hrs) Diesel fuel system components -

Description and function of Diesel tanks

69 Bleed air from the fuel lines, & lines, Diesel fuel filters, water separator,

Servicingprimary & secondary Lift pump, Plunger pump, Priming pump,

filters. (15 Hrs)

Electronic Diesel control- Electronic

70 Remove a fuel injection pump from

an engine-refit the pump to the Diesel control systems, Common Rail

engine re- set timing - fill Diesel Injection (CRDI) system, Sensors,

lubricating-oil start and adjust actuators and ECU (Electronic Control

slow speed of the engine. (15 Unit) used in Diesel Engines.(08 hrs)

Hrs)

(xv)