Page 18 - MMV 1st Year - TT - Telugu

P. 18

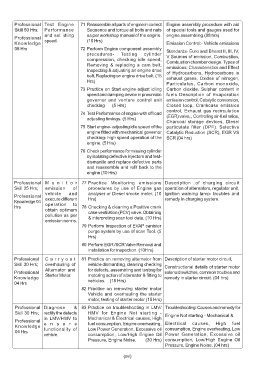

Professional Test Engine 71 Reassemble all parts of engine in correct Engine assembly procedure with aid

Skill 50 Hrs; Performance Sequence and torque all bolts and nuts of special tools and gauges used for

and set idling as per workshop manual of the engine. engine assembling.(08 hrs)

Professional

Knowledge speed. (10 Hrs) Emission Control:- Vehicle emissions

08 Hrs 72 Perform Engine component assembly Standards- Euro and Bharat II, III, IV,

procedures- Testing cylinder V Sources of emission, Combustion,

compression, checking idle speed, Combustion chamber design. Types of

Removing & replacing a cam belt, emissions: Characteristics and Effect

Inspecting & adjusting an engine drive of Hydrocarbons, Hydrocarbons in

belt, Replacing an engine drive belt. (15 exhaust gases, Oxides of nitrogen,

Hrs)

Particulates, Carbon monoxide,

73 Practice on Start engine adjust idling Carbon dioxide, Sulphur content in

speed and damping device in pneumatic fuels Description of Evaporation

governor and venture control unit emission control, Catalytic conversion,

checking (5 Hrs) Closed loop, Crankcase emission

control, Exhaust gas recirculation

74 Test Performance of engine with off load (EGR) valve, , Controlling air-fuel ratios,

adjusting timings. (5 Hrs)

Charcoal storage devices, Diesel

75 Start engine- adjusting idle speed of the particulate filter (DPF). Selective

engine fitted with mechanical governor Catalytic Reduction (SCR), EGR VS

checking- high speed operation of the SCR (04 hrs)

engine. (5 Hrs)

76 Check performance for missing cylinder

by isolating defective injectors and test-

dismantle and replace defective parts

and reassemble and refit back to the

engine (10 Hrs)

Professional Monitor 77 Practice Monitoring emissions Description .of charging circuit

Skill 35 Hrs; emission of procedures by use of Engine gas operation of alternators, regulator unit,

vehicle and analyser or Diesel smoke meter. (10 ignition warning lamp- troubles and

Professional execute different Hrs) remedy in charging system.

Knowledge 04 operation to

Hrs 78 Checking & cleaning a Positive crank

obtain optimum case ventilation (PCV) valve. Obtaining

pollution as per & interpreting scan tool data. (10 Hrs)

emission norms.

79 Perform Inspection of EVAP canister

purge system by use of scan Tool. (5

Hrs)

80 Perform EGR /SCR Valve Removal and

installation for inspection. (10Hrs)

Professional Carryout 81 Practice on removing alternator from Description of starter motor circuit,

Skill 30 Hrs; overhauling of vehicle dismantling, cleaning checking Constructional details of starter motor

Alternator and for defects, assembling and testing for

Professional Starter Motor. motoring action of alternator & fitting to solenoid switches, common troubles and

Knowledge vehicles. (15 Hrs) remedy in starter circuit. (04 hrs)

04 Hrs

82 Practice on removing starter motor

Vehicle and overhauling the starter

motor, testing of starter motor (15 Hrs)

Professional Diagnose & 83 Practice on troubleshooting in LMV/ Troubleshooting: Causes and remedy for

Skill 30 Hrs; rectify the defects HMV for Engine Not starting - Engine Not starting - Mechanical &

in LMV/HMV to Mechanical & Electrical causes, High

Professional

Knowledge ensure fuel consumption, Engine overheating, Electrical causes, High fuel

04 Hrs functionality of Low Power Generation, Excessive oil consumption, Engine overheating, Low

vehicle. consumption, Low/High Engine Oil Power Generation, Excessive oil

Pressure, Engine Noise. (30 Hrs) consumption, Low/High Engine Oil

Pressure, Engine Noise. (04 hrs)

(xvi)