Page 419 - Content.pmd

P. 419

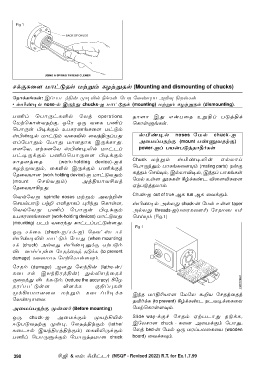

Fig 1

BACK OF CHUCK

USING A SPRING THREAD CLENER

NdÏLû[ UôhÓRp Utßm LZtßRp (Mounting and dismounting of chucks)

úSôdLeLs: ClTôPj§u Ø¥®p ¿eLs ùT\ úYi¥V A±Ü §\uLs

• v©i¥p noseþp CÚkÕ chucksþI UôhÓRp (mounting) Utßm LZtßRp (dismounting).

T¦l ùTôÚhL°p úXj operations Rô]ô CÕ GuTûR Eߧl TÓj§d

úUtùLôsYRtÏ, JúW JÚ YûL T¦l ùLôsÞeLs.

ùTôÚs ©¥dÏm ETLWQeLû[ UhÓm

v©i¥p UôhÓm YûL«p ûYj§ÚlTÕ v©i¥p noses úUp chuckþI

GlúTôÕm úTôÕ Uô]RôL CÚdLôÕ. AûUlTRtÏ (mount TiÔYRtÏ)

G]úY, HtL]úY v©i¥Xõp UôhPl powerþIl TVuTÓjRô¾oLs

Th¥ÚdÏm T¦lùTôÚû[ ©¥dÏm

Chuck Utßm v©i¥Xõu GpXôl

NôR]jûR (work-holding device)þId

ùTôÚkÕm TôLeLû[Ùm (mating parts) SuÏ

LZtßYÕm, ûL«p CÚdÏm T¦dÏj

ÑjRm ùNnÙm, CpXô®¥p, CkRl TôLeLs

úRûYVô] (work holding device)þI UôhÓYÕm

(mount ùNnYÕm) Aj§VôY£Vj úUp Es[ çÑLs ¸rdLiP ®û[®Lû[

HtTÓjRXôm.

úRûYVô¡\Õ.

Chuck-I out of true BL run BL ûYdÏm.

ùYqúYß spindle noses Utßm AYt±u

ùNVpTôÓ Tt± G°RôLl ׬kÕ ùLôs[, v©i¥p ApXÕ chuckþu úUp Es[ taper

ùYqúYß T¦l ùTôÚs ©¥dÏm ApXÕ threadsþI(UûWLû[f) úNRUûPVf

ETLWQeLû[ (work-holding devices) UôhÓYÕ ùNnÙm (Fig.1)

(mounting) TPm YûWkÕ LôhPlThÓs[Õ.

JÚ NdûL (chuckþI/NdþI) ùahvPôd

v©i¥Xõp UôhÓm úTôÕ (when mounting)

Nd (chuck) ApXÕ v©i¥ÛdÏ HtTÓm

®P Yônl×s[ úNRjûRj RÓdL (to prevent

damage) LY]UôL úUtùLôs[Üm.

úNRm (damage) B]Õ úXj§u (latheþu/

LûPNp CVk§Wj§u) ÕpXõVjûRd

Ïû\jÕ ®PdáÓm. (reduce the accuracy) ¸úZ

RWlThÓs[ ®[dL ϱl×Ls

Ød¡VUô]ûY Utßm LûPl©¥dL CkR Uô§¬Vô] úUúX á±V úNRjûRj

úYi¥VûY. R®odL (to prevent) ¸rdLiP SPY¥dûLûV

AûUlTRtÏ Øu]o (Before mounting) úUtùLôs[Üm.

JÚ chuckþI AûUdÏm ØVt£«p Slide way-dÏf úNRm HtTPôÕ RÓdL,

DÓTÓYRtÏ Øu×, úXRj§tÏm (lathe/ CúXNô] chuck - Lû[ AûUdÏm úTôÕ,

LûPNp CVk§Wj§tÏm) ûL«XõÚdÏm úXj bedþu úUp JÚ UWlTXûLûV (wooden

T¦l ùTôÚÞdÏm ùTôÚjRUô] chuck board) ûYdLÜm.

398 £_õ & Gm: @©hPo (NSQF - Revised 2022) R.T. for Ex.1.7.99