Page 409 - Content.pmd

P. 409

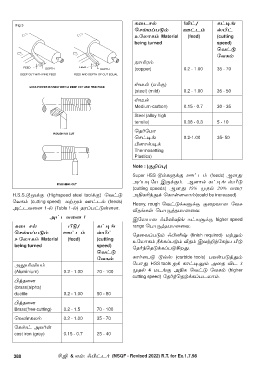

Fig 3 LûPNp f«h/ Lh¥e

ùNnVlTÓm FhPm vÀh

EúXôLm Material (feed) (cutting

being turned speed)

ùYhÓ

úYLm

RôªWm

FEED DEPTH FEED DEPTH (copper) 0.2 - 1.00 35 - 70

DEEP CUT WITH FINE FEED FEED AND DEPTH OF CUT EQUAL

v¼p (G@Ï)

LESS POWER IS USED WITH A DEEP CUT AND FINE FEED

(steel) (mild) 0.2 - 1.00 35 - 50

v¼p

Medium-carbon) 0.15 - 0.7 30 - 35

Steel (alloy high

tensile) 0.08 - 0.3 5 - 10

ùRoúUô

ROUGHING CUT

ùNh¥e 0.2-1.00 35- 50

©[ôv¥d

Thermosetting

Plastics)

Note : (ϱl×)

Super HSS åpLÞdÏ FhPm (feeds) B]Õ

AlT¥úV CÚdÏm. B]ôp Lh¥e vÀÓ

FINISHING CUT

(cutting speeds) B]Õ 15% ØRp 20% YûW

H.S.S.åÛdÏ (Highspeed steel tooldÏ) ùYhÓ A§L¬jÕd ùLôs[Xôm(could be increased)

úYLm (cutting speed) Utßm FhPm (feeds)

Heavy, rough ùYhÓdLÞdÏ Ïû\Yô] úYL

AhPYû] 1þp (Table 1þp) RWlThÓs[].

ÅReLs ùTôÚjRUô]ûY.

AhPYû] 1

CúXNô] @©²μe LhLÞdÏ higher speed

LûPNp ÀÓ/ Lh¥e range ùTôÚjRUô]ûY,

ùNnVlTÓm FhPm vÀh úRûYlTÓm @©²x (finish required) Utßm

EúXôLm Material (feed) (cutting EúXôLm ¿dLlTÓm ÅRm CYt±túLtT ÀÓ

being turned speed)

úRokùRÓdLlTÓ¡\Õ.

ùYhÓ

úYLm LôoûTÓ åpv (carbide tools) TVuTÓjÕm

AÛª²Vm úTôÕ HSS tools Id Lôh¥Ûm AûR ®P 3

(Aluminium) 0.2 - 1.00 70 - 100 ØRp 4 UPeÏ A§L ùYhÓ úYLm (higher

cutting speed) úRokùRÓdLlTPXôm.

©jRû[

(brass(alpha)

ductile 0.2 - 1.00 50 - 80

©jRû[

Brass(free cutting) 0.2 - 1.5 70 - 100

ùYiLXm 0.2 - 1.00 35 - 70

úLvh AVou

cost iron (grey) 0.15 - 0.7 25 - 40

388 £_õ & Gm: @©hPo (NSQF - Revised 2022) R.T. for Ex.1.7.98