Page 408 - Content.pmd

P. 408

Fig 2 T¦lùTôÚs EúXôLj§u ÏQm (Property

of work) material

T¦lùTôÚ°u Eߧj RuûU (rigidity)

TVuTÓjRlTÓm Lh¥e @lð«¥u YûL

(Type of cutting fluid)

CVk§Wj§u Eߧj RuûU (¬´¥h¥/

rigidity)

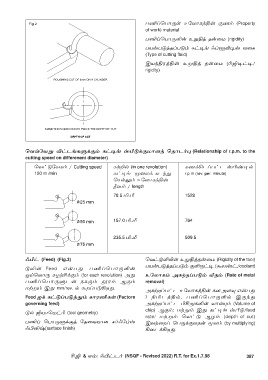

ROUGHING CUT OF 3mm ON A CYLINDER

DIAMETER IS REDUCED BY TWICE THE DEPTH OF CUT

DEPTH OF CUT

ùYqúYß ®hPeLÞdÏm Lh¥e vÀÓdÏUô]j ùRôPo× (Relationship of r.p.m. to the

cutting speed on differenent diameter)

ùYhÓúYLm / Cutting speed Ñt±p (in one revolution) LQd¡PlThP v©i¥p

120 m /min Lh¥e êûXd LPkÕ r.p.m (rev. per. minute)

ùNpÛm EúXôLj§u

¿[m / length

78.5 ª..Á 1528

25 mm

50 mm 157.0 ª..Á 764

235.5 ª..Á 509.5

75 mm

@Àh (Feed) (Fig.3) ùYhÓ°«u EߧjRuûU (Rigidity of the tool)

TVuTÓjRlTÓm Ï°ìh¥ (áXih/coolant)

åXõu Feed GuTÕ T¦lùTôÚ°u

JqùYôÚ ÑZt£dÏm (for each revolution) AÕ EúXôLm ALt\lTÓm ÅRm (Rate of metal

T¦lùTôÚÞPu SLÚm çWm BÏm removal)

Utßm CÕ mm/rev. p á\lTÓ¡\Õ.

ALt\lThP EúXôLj§u L]A[Ü GuTÕ

Feed Id LhÓlTÓjÕm LôW¦Ls (Factors 1 ¨ªPj§p, T¦lùTôÚ°p CÚkÕ

governing feed) ALt\lThP ©£ßL°u YôpÙm (Volume of

chip) BÏm; Utßm CÕ Lh¥e vÀÓ/feed

åp ´VôùUh¬ (tool geometry)

rate/ Utßm ùYhÓ BZm (depth of cut)

T¦l ùTôÚÞdÏj úRûYVô] No@úTóv CYtû\l ùTÚdÏYRu êXm (by multiplying)

@©²x(surface finish) ¡ûPd¡\Õ.

£_õ & Gm: @©hPo (NSQF - Revised 2022) R.T. for Ex.1.7.98 387