Page 399 - Content.pmd

P. 399

(T¦lùTôÚ°u) NWôN¬ ®hPj§túLtT CÚlTRôÏm. (tool is not clamped rigidly).

v©i¥p r.p.m revolution per minute) Ïû\kRThN KYo úae (minimum overhang)

úRokRÓjÕ W@l @úT³e (rough facing) EPu åûX (tool) EߧVôL ¡[ôml

ùNnVlTÓ¡\Õ. TiÔYRu êXm (by clamping the tool rigidly)

CkRd Ïû\TôhûPj R®odLXôm.

W@l @úT³e¡tÏj (rough facing-¡tÏj)

úRokùRÓdLlTÓm ùYhÓúYLjûRl (cutting Ï®ÜØLl× (A convex face) LôuùYdv

speed Il) úTôp CWiÓ UPeÏ ùYhÓ úTv

úYLjûRj úRokùRÓjÕ @ûTu @ÀÓ úWh

CkRd Ïû\Tôh¥tLô] LôWQm

(fine feed rate) úRôWôVUôL 0.05ªÁ EPu

ùYhÓ°«u ùYhÓ®°m× Øû] UÝe¡

Utßm 0.1 ªÁ I ®PdÏû\Yô] ùYhÓ

CÚlTRôÏm ApXÕ AÕ TV¦dÏm úTôÕ

BZjÕPu (depth of cut) @©²x @úT³e

Øû] UÝe¡d ùLôiúP (getting blunt)

ùNnVlTÓ¡\Õ.

CÚlTRôÏm, Utßm úLúWw éhPlTPôUp

ØLl×d LûPNp ùNnVlThP CÚjRp (not being locked) CdÏû\TôhûPj

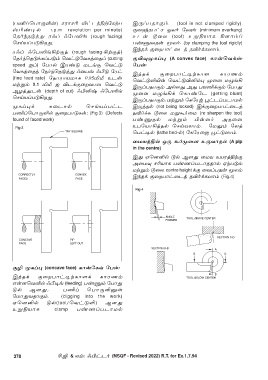

T¦lùTôÚ°p Ïû\TôÓLs: (Fig 3) (Defects R®odL åûX UßáoûU (re sharpen the tool)

found of faced work) TiÔRp Utßm ©u]o ARû]

Fig 3 ETúVô¡jRp ùNnVXôm. úUÛm úXj

TRY SQUARE ùTh¥p (lathe bedþp) úLúWû_ éhÓXôm.

ûUVj§p JÚ áoØû] EÚYôRp (A pip

in the centre)

CÕ Hù]²p åp B]Õ ûUV EVWj§tÏ

AûUÜ N¬VôL TiQlTPôRRôp HtTÓm

Utßm åûX centre height dÏ ûYlTRu êXm

CORRECTLY CONVEX CkRd Ïû\TôhûPj R®odLXôm (Fig.4)

FACED FACE

Fig 4

ANGLE TOOL ABOVE CENTER

FORMED

SECTION C-D

CONCAVE PIP

FACE LEFT OUT

SECTION A-B A

B D

ϯ ØLl× (concave face) LôuúLq úTv

B

CkRd Ïû\Tôh¥tLô]d LôWQm TOOL BELOW CENTER

Gu]ùY²p @À¥e (feeding) TiÔm úTôÕ

åp B]Õ, T¦l ùTôÚ°às

úUôÕYRôÏm. (digging into the work)

Hù]²p åp(tool/ùYhÓ°) B]Õ

EߧVôL clamp TiQlTPôUp

378 £_õ & Gm: @©hPo (NSQF - Revised 2022) R.T. for Ex.1.7.94