Page 281 - Content.pmd

P. 281

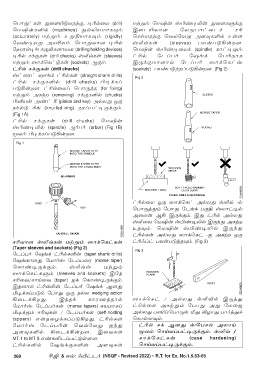

ùTôÚhLs Õû[«ÓYRtÏ, ¥¬pûX (drill) Utßm ùUμu v©i¥Xõu Õû[LÞdÏ

ùUμuL°p (machines) ÕpXõVUôLÜm CûP«Xô] úYßTôhûPf N¬

(accurately) Utßm EߧVôLÜm (rigidly) ùNnYRtÏ ùYqúYß A[ÜL°p Es[

úYi¥VÕ AY£Vm. ùTôÕYô] ¥¬p vÄqLs (sleeves) TVuTÓ¡u\].

úaôp¥e LÚ®L[ôY] (drilling holding devices) ùUμu v©i¥ûXd (spindle) Lôh¥Ûm

¥¬p NdÏLs (drill chucks) vÄqLs (sleeves) h¬p úPlTo ú`ed ùT¬RôL

Utßm ^ôdùLhÓLs (sockets) BÏm. CÚdÏUô]ôp úPlTo ^ôdùLhv

h¬p NdÏLs (drill chucks) (sockets) TVuTÓjRlTÓ¡u\]. (Fig 2)

vhûWh `ôed h¬pLs (straight shank drills)

h¬p NdÏL°p (drill chucks) ©¥dLl

TÓ¡u\]. h¬pûXl ùTôÚjR (for fixing)

Utßm ALt\ (removing) NdÏL°p (chucks)

©²Vu Aih ¸ (pinion and key) ApXÕ JÚ

SopÓ ¬e (knurled ring) RWlTh¥ÚdÏm.

(Fig 1A)

h¬p NdÏLs (drill chucks) ùUμu

v©i¥Xõp (spindle) BoTo (arbor) (Fig 1B)

êXm ©¥dLlTÓ¡u\].

h¬pûX JÚ ^ôdùLh ApXÕ vÄq þp

ùTôÚjÕm úTôÕ úPed Tϧ vXôh¥p

AûXu B¡ CÚdÏm. CÕ h¬p ApXÕ

vÄûY ùUμu v©i¥Xõp CÚkÕ ALt\

ERÜm. ùUμu v©i¥Xõp CÚkÕ

h¬pLs ApXÕ ^ôdùLh þI ALt\ JÚ

N¬Yô] vÄqLs Utßm ^ôdùLhLs h¬@lh TVuTÓjRÜm. (Fig 3)

(Taper sleeves and sockets) (Fig 2)

úPlTo ú`ed h¬pL°u (taper shank drills)

ú`eLô]Õ úUôov úPlTûW (morse taper)

ùLôi¥ÚdÏm. vÄqv Utßm

^ôdùLhLÞm (sleeves and sockets) CúR

N¬ûY/NônûY (taper) Id ùLôi¥ÚdÏm.

CR]ôp h¬pXõu úPlTo ú`ed B]Õ

©¥dLlTÓm úTôÕ JÚ SpX wedging action

¡ûPd¡\Õ. CkRd LôWQjRôp ^ôdùLh / ApXÕ vÄ®p CÚkÕ

úUôov úPlToLs (morse tapers) ÑVUôLl h¬pûX ALtßm úTôÕ AÕ úUû_

©¥dÏm N¬ÜLs / úPlToLs (self-holding ApXÕ T¦lùTôÚs ÁÕ ®ZôÕ TôojÕd

tappers) Gu\ûZdLlTÓ¡\Õ. h¬pLs ùLôs[Üm.

úUôov úPlT¬u ùYqúYß IkÕ h¬p Nd B]Õ vùTNp AXôn

A[ÜL°p ¡ûPd¡u\]. CûYLs êXm ùNnVlTh¥ÚdÏm. vÄq /

MT 1 to MT 5 GiL°PlThÓs[]. NôdùLhLs (case hardening)

h¬pL°p ú`edÏL°u A[ÜLs ùNnVlTh¥ÚdÏm.

260 £_õ & Gm: @©hPo (NSQF - Revised 2022) ------ R.T. for Ex. No.1.5.63-65