Page 277 - Content.pmd

P. 277

CkR úWd Be¡s GuTÕ lðh¥u

(ØßdÏ) úLôQUôÏm.

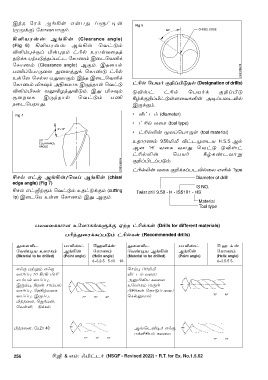

¡°VWuv Be¡s (Clearance angle)

(Fig 6) ¡°VWuv Be¡s ùYhÓm

®°m×dÏl ©u×\m h¬p EWônYûRj

RÓdL HtTÓjRlThP úLôQm CûPùY°d

úLôQm (Clearance angle) BÏm. CR]ôp

T¦lúTôÚû[ Õû[jÕd ùLôiÓ h¬p

Esú[ ùNpX HÕYôÏm. CkR CûPùY°d

úLôQm ªLÜm A§LUôL CÚkRôp ùYhÓ h¬p ùTVo ϱl©ÓRp (Designation of drills)

®°m©Ls YÛ®ZkÕ®Óm. CÕ ªLÜm Ó®vh h¬p ùTVod ϱlÀÓ

Ïû\YL CÚkRôp ùYhÓm T¦ ¸rdϱl©hÓs[ûYL°u A¥lTûP«p

SûPùT\ôÕ. CÚdÏm.

• ®hPm (diameter)

• h¬p YûL (tool type)

• h¬pXõu êXlùTôÚs (tool material)

ERôWQm 9.50ª.Á ®hPØûPV H.S.S Bp

B] ‘H’ YûL YXÕ ùYhÓ Ó®vh

h¬pXõu ùTVo ¸rLiPYôß

ϱl©PlTÓm.

h¬pXõu YûL ϱdLlTP®pûX G²p Type

£Np Ghw Be¡s/ùYl Be¡s (chisel Diameter of drill

edge angle) (Fig 7)

IS NO.

£Np Gh´tÏm ùYhÓm ERhÓdÏm (cutting Twist drill 9.50 - H - IS5101 - HS

lip) CûPúV Es[ úLôQm CÕ BÏm.

Material

Tool type

TXYûLVô] EúXôLeLÞdÏ Ht\ h¬pLs (Drills for different materials)

T¬kÕûWdLlTÓm h¬pLs (Recommended drills)

Õû[«P Tô«ih ùa≠dv Õû[«P Tô«ih ùa-dv

úYi¥V EXôLm Be¡s úLôQm úYi¥V Be¡s Be¡s úLôQm

(Material to be drilled) (Point angle) (Helix angle) (Material to be drilled) (Point angle) (Helix angle)

d=3.2-5 5-10 10- d=3.5-5 5-

G@Ï Utßm G@Ï ùNm× (30ª.Á

Yôol× 70 ¡/¡ ªÁ 2 ®hPm YûW)

NômTp Yôol×, AÛª²V LXûY

CÚm×, §\u NômTp EúXôLm (ÑÚs

Yôol×, ùS¡rYûL ©£oLs ùLôÓlTûY)

Yôol×, CÚm×, ùNpÛXôn

©jRû[, ù_oUu,

ùYs°, ¨dLp

©jRû[, CuZn 40 BvùP²¥d G@Ï,

UdÉ£Vm LXûY

256 £_õ & Gm: @©hPo (NSQF - Revised 2022) - R.T. for Ex. No.1.5.62