Page 19 - Welder - TP - Kannada

P. 19

SYLLABUS

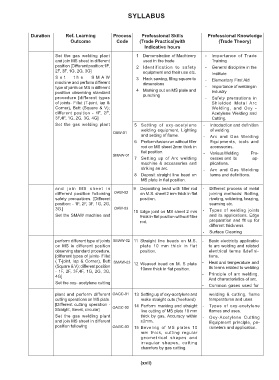

Duration Ref. Learning Process Professional Skills Professional Knowledge

Outcome Code (Trade Practical)with (Trade Theory)

Indicative hours

Set the gas welding plant 1 Demonstration of Machinery - Importance of Trade

and join MS sheet in different used in the trade Training

position [Different position:1F, 2 Identification to safety - General discipline in the

2F, 3F, 1G, 2G, 3G] equipment and their use etc. Institute

Set the SMA W 3 Hack sawing, filing square to - Elementary First Aid

machine and perform different dimensions

type of joints on MS in different - Importance of welding in

position observing standard 4 Marking out on MS plate and industry

procedure [different types punching - Safety precautions in

of joints- Fillet (T-joint, lap & Shielded Metal Arc

Corner), Butt (Square & V); Welding, and Oxy -

different position - 1F, 2F, Acetylene Welding and

3F,4F, 1G, 2G, 3G, 4G] Cutting.

Set the gas welding plant 5 Setting of oxy-acetylene - Introduction and definition

welding equipment, Lighting of welding.

OAW-01

and setting of flame. - Arc and Gas Welding

6 Perform fusion run without filler Equipments, tools and

rod on MS sheet 2mm thick in accessories.

flat position. - Various Welding Pro-

SMAW-01

7 Setting up of Arc welding cesses and its ap-

machine & accessories and plications.

striking an arc. - Arc and Gas Welding

8 Deposit straight line bead on terms and definitions.

MS plate in flat position.

and join MS sheet in 9 Depositing bead with filler rod - Different process of metal

different position following OAW-02 on M.S. sheet 2 mm thick in flat joining methods: Bolting,

safety precautions. [Different position. riveting, soldering, brazing,

position: - 1F, 2F, 3F, 1G, 2G, seaming etc.

3G.] OAW-03 10 Edge joint on MS sheet 2 mm - Types of welding joints

Set the SMAW machine and thick in flat position without filler and its applications. Edge

rod. preparation and fit up for

different thickness.

- Surface Cleaning

perform different type of joints SMAW-02 11 Straight line beads on M.S. - Basic electricity applicable

on MS in different position plate 10 mm thick in flat to arc welding and related

observing standard procedure. position. electrical terms &defini-

[different types of joints- Fillet tions.

( T-joint, lap & Corner), Butt SMAW-03 - Heat and temperature and

(Square & V); different position 12 Weaved bead on M. S plate its terms related to welding

- 1F, 2F, 3F,4F, 1G, 2G, 3G, 10mm thick in flat position. - Principle of arc welding.

4G] And characteristics of arc.

Set the oxy- acetylene cutting

- Common gases used for

plant and perform different OAGC-01 13 Setting up of oxy-acetylene and welding & cutting, flame

cutting operations on MS plate. make straight cuts (freehand) temperatures and uses.

[Different cutting operation - 14 Perform marking and straight - Types of oxy-acetylene

Straight, Bevel, circular] OAGC-02 line cutting of MS plate 10 mm flames and uses.

Set the gas welding plant thick by gas. Accuracy within - Oxy-Acetylene Cutting

and join MS sheet in different ±2mm. Equipment principle, pa-

position following OAGC-03 15 Beveling of MS plates 10 rameters and application.

mm thick, cutting regular

geometrical shapes and

irregular shapes, cutting

chamfers by gas cutting.

(xvii)