Page 21 - Welder(Pipe) - TP - Hindi

P. 21

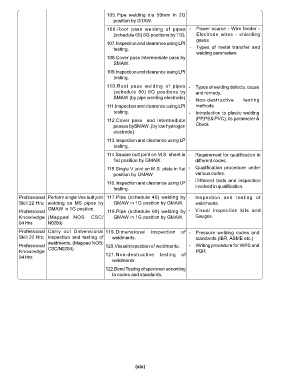

105.Pipe welding dia 50mm in 2G

position by GTAW.

106.Root pass welding of pipes - Power source - Wire feeder -

(schedule 60) 6G positions by TIG. Electrode wires - shielding

gases

107.Inspection and clearance using LPI

testing. - Types of metal transfer and

welding parameters

108.Cover pass Intermediate pass by

SMAW.

109.Inspection and clearance using LPI

testing.

110.Root pass welding of pipes - Types of welding defects, cause

(schedule 80) 6G positions by and remedy.

SMAW (by pipe welding electrode)

- Non-destructive testing

111.Inspection and clearance using LPI methods.

testing. - Introduction to plastic welding

112.Cover pass and Intermediate (PP,PE& PVC), its parameter &

passes bySMAW. (by low hydrogen Check

electrode)

113.Inspection and clearance using LP

testing.

114.Square butt joint on M.S. sheet in - Requirement for qualification in

flat position by GMAW. different codes.

115.Single V joint on M.S. plate in flat - Qualification procedure under

position by GMAW. various codes.

- Different tests and inspection

116.Inspection and clearance using LP

testing. involved in qualification.

Professional Perform single Vee butt joint 117.Pipe (schedule 40) welding by - Inspection and testing of

Skill 22 Hrs; welding on MS pipes by GMAW in 1G position by GMAW. weldments.

GMAW in 1G position.

Professional 118.Pipe (schedule 60) welding by - Visual inspection kits and

Knowledge (Mapped NOS: CSC/ GMAW in 1G position by GMAW. Gauges.

04 Hrs N0209)

Professional Carry out Dimensional 119.Dimensional inspection of - Pressure welding codes and

Skill 22 Hrs; inspection and testing of weldments. standards (IBR, ASME etc.)

weldments. (Mapped NOS:

Professional 120.Visual inspection of weldments. - Writing procedure for WPS and

Knowledge CSC/N0204) PQR

04 Hrs 121.Non-destructive testing of

weldments

122.Bend Testing of specimen according

to codes and standards.

(xix)