Page 19 - Welder(Pipe) - TP - Hindi

P. 19

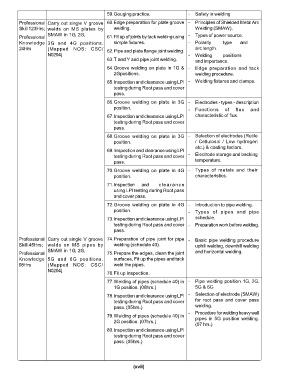

59.Gouging practice. - Safety in welding

Professional Carry out single V groove 60.Edge preparation for plate groove - Principles of Shielded Metal Arc

Skill 123Hrs; welds on MS plates by welding. Welding (SMAW).

SMAW in 1G, 2G, - Types of power source.

Professional 61.Fit up of joints by tack welding using

Knowledge 3G and 4G positions. simple fixtures. - Polarity type and

24Hrs (Mapped NOS: CSC/ 62.Pipe and plate flange joint welding. arc length.

N0204) - Welding positions

63.T and Y and pipe joint welding. and importance.

64.Groove welding on plate in 1G & - Edge preparation and tack

2Gpositions. welding procedure.

65.Inspection and clearance using LPI - Welding fixtures and clamps.

testing during Root pass and cover

pass.

66.Groove welding on plate in 3G - Electrodes - types - description

position. - Functions of flux and

67.Inspection and clearance using LPI characteristic of flux.

testing during Root pass and cover

pass.

68.Groove welding on plate in 3G - Selection of electrodes (Rutile

position. / Cellulosic / Low hydrogen

etc.) & coating factors.

69. Inspection and clearance using LPI

testing during Root pass and cover - Electrode storage and backing

pass. temperature.

70.Groove welding on plate in 4G - Types of metals and their

position. characteristics.

71.Inspection and clearance

using LPI testing during Root pass

and cover pass.

72.Groove welding on plate in 4G - Introduction to pipe welding.

position. - Types of pipes and pipe

73.Inspection and clearance using LPI schedule.

testing during Root pass and cover - Preparation work before welding.

pass.

Professional Carry out single V groove 74.Preparation of pipe joint for pipe - Basic pipe welding procedure

Skill 45Hrs; welds on MS pipes by welding (schedule 40). uphill welding, downhill welding

SMAW in 1G, 2G, and horizontal welding.

Professional 75.Prepare the edges, clean the joint

Knowledge 5G and 6G positions. surfaces, Fit up the pipes and tack

08Hrs (Mapped NOS: CSC/ weld the pipes.

N0204)

76.Fit up inspection.

77.Welding of pipes (schedule 40) in - Pipe welding position 1G, 2G,

1G position. (08hrs.) 5G & 6G

78.Inspection and clearance using LPI - Selection of electrode (SMAW)

testing during Root pass and cover for root pass and cover pass

pass. (05hrs.) welding.

- Procedure for welding heavy wall

79.Welding of pipes (schedule 40) in pipes in 5G position welding.

2G position. (07hrs.)

(07 hrs.)

80.Inspection and clearance using LPI

testing during Root pass and cover

pass. (05hrs.)

(xvii)