Page 20 - Fitter 1st Year - TP - Hindi

P. 20

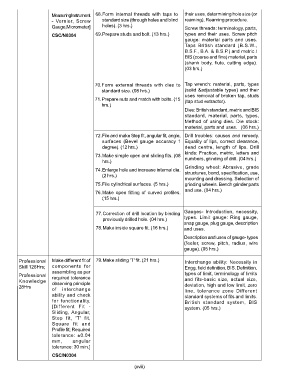

MeasuringInstrument 68.Form internal threads with taps to their uses, determining hole size (or

- Vernier, Screw standard size (through holes and blind reaming), Reaming procedure.

Gauge,Micrometer] holes). (3 hrs.) Screw threads: terminology, parts,

CSC/N0304 69.Prepare studs and bolt. (13 hrs.) types and their uses. Screw pitch

gauge: material parts and uses.

Taps British standard (B.S.W.,

B.S.F., B.A. & B.S.P.) and metric /

BIS (coarse and fine) material, parts

(shank body, flute, cutting edge).

(03 hrs.)

70.Form external threads with dies to Tap wrench: material, parts, types

standard size. (08 hrs.) (solid &adjustable types) and their

uses removal of broken tap, studs

71.Prepare nuts and match with bolts. (15 (tap stud extractor).

hrs.)

Dies: British standard, metric and BIS

standard, material, parts, types,

Method of using dies. Die stock:

material, parts and uses. (06 hrs.)

72.File and make Step fit, angular fit, angle, Drill troubles: causes and remedy.

surfaces (Bevel gauge accuracy 1 Equality of lips, correct clearance,

degree). (12 hrs.) dead centre, length of lips. Drill

kinds: Fraction, metric, letters and

73.Make simple open and sliding fits. (08 numbers, grinding of drill. (04 hrs.)

hrs.)

Grinding wheel: Abrasive, grade

74.Enlarge hole and increase internal dia.

(2 hrs.) structures, bond, specification, use,

mounting and dressing. Selection of

75.File cylindrical surfaces. (5 hrs.) grinding wheels. Bench grinder parts

and use. (04 hrs.)

76.Make open fitting of curved profiles.

(15 hrs.)

77.Correction of drill location by binding Gauges- Introduction, necessity,

previously drilled hole. (04 hrs.) types. Limit gauge: Ring gauge,

snap gauge, plug gauge, description

78.Make inside square fit. (16 hrs.) and uses.

Description and uses of gauge- types

(feeler, screw, pitch, radius, wire

gauge). (05 hrs.)

Professional Make different fit of 79.Make sliding 'T' fit. (21 hrs.) Interchange ability: Necessity in

Skill 126Hrs; components for Engg, field definition, BIS. Definition,

assembling as per types of limit, terminology of limits

Professional required tolerance

Knowledge observing principle and fits-basic size, actual size,

28Hrs deviation, high and low limit, zero

of interchange line, tolerance zone Different

ability and check standard systems of fits and limits.

for functionality. British standard system, BIS

[Different Fit - system. (05 hrs.)

Sliding, Angular,

Step fit, 'T' fit,

Square fit and

Profile fit; Required

tolerance: ±0.04

mm, angular

tolerance: 30 min.]

CSC/N0304

(xviii)