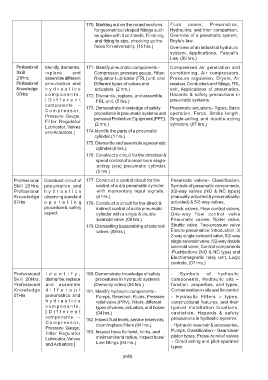

Page 20 - Fitter - 1st Year - TP- Gujarati

P. 20

170. Marking out on the round sections Fluid power, Pneumatics,

for geometrical shaped fittings such Hydraulics, and their comparison,

as spline with 3 or 4 teeth. Finishing Overview of a pneumatic system,

and fitting to size, checking up the Boyle’s law.

faces for universality. (15 hrs.) Overview of an industrial hydraulic

system, Applications, Pascal’s

Law. (05 hrs.)

Professional Identify, dismantle, 171. Identify pneumatic components – Compressed air generation and

Skill replace and Compressor, pressure gauge, Filter- conditioning, Air compressors,

21Hrs; assemble different Regulator-Lubricator (FRL) unit, and Pressure regulation, Dryers, Air

Professional pneumatics and Different types of valves and receiver, Conductors and fittings, FRL

Knowledge hydraulics actuators. (2 hrs.) unit, Applications of pneumatics,

07Hrs components. 172. Dismantle, replace, and assemble Hazards & safety precautions in

[Different FRL unit. (5 hrs.) pneumatic systems.

components – 173. Demonstrate knowledge of safety Pneumatic actuators:- Types, Basic

Compressor , procedures in pneumatic systems and operation, Force, Stroke length,

Pressure Gauge, personal Protective Equipment (PPE). Single-acting and double-acting

Filter Regulator (2 hrs.) cylinders. (07 hrs.)

Lubricator, Valves

and Actuators.] 174.Identify the parts of a pneumatic

cylinder.(1 hrs.)

175. Dismantle and assemble a pneumatic

cylinder.(6 hrs.)

176. Construct a circuit for the direction &

speed control of a small-bore single-

acting (s/a) pneumatic cylinder.

(5 hrs.)

Professional Construct circuit of 177. Construct a control circuit for the Pneumatic valves:- Classification,

Skill 20Hrs; pneumatics and control of a d/a pneumatic cylinder Symbols of pneumatic components,

Professional hydraulics with momentary input signals. 3/2-way valves (NO & NC types)

Knowledge observing standard (4 hrs.) (manually-actuated & pneumatically-

07Hrs operating 178. Construct a circuit for the direct & actuated) & 5/2-way valves,

procedure& safety indirect control of a d/a pneumatic Check valves, Flow control valves,

aspect. cylinder with a single & double One-way flow control valve

solenoid valve. (08 hrs.) Pneumatic valves: Roller valve,

179. Dismantling &assembling of solenoid Shuttle valve, Two-pressure valve

valves. (08hrs.) Electro-pneumatics: Introduction, 3/

2-way single solenoid valve, 5/2-way

single solenoid valve, 5/2-way double

solenoid valve, Control components

-Pushbuttons (NO & NC type) and

Electromagnetic relay unit, Logic

controls. (07 hrs.)

Professional Identify , 180. Demonstrate knowledge of safety - Symbols of hydraulic

Skill 20Hrs; dismantle, replace procedures in hydraulic systems components, Hydraulic oils –

Professional and assemble (Demo by video) (04 hrs.) function, properties, and types,

Knowledge different 181. Identify hydraulic components – Contamination in oils and its control

07Hrs pneumatics and Pumps, Reservoir, Fluids, Pressure - Hydraulic Filters – types,

hydraulics relief valve (PRV), Filters, different constructional features, and their

components. types of valves, actuators, and hoses typical installation locations,

[Different (04 hrs.) cavitation, Hazards & safety

components – 182. Inspect fluid levels, service reservoirs, precautions in hydraulic systems

Compressor , clean/replace filters (04 hrs.) - Hydraulic reservoir & accessories,

Pressure Gauge, Pumps, Classification – Gear/vane/

Filter Regulator 183. Inspect hose for twist, kinks, and piston types, Pressure relief valves

Lubricator, Valves minimum bend radius, Inspect hose/ – Direct acting and pilot-operated

and Actuators.] tube fittings (04 hrs.)

types

(xviii)