Page 16 - Fitter - 1st Year - TP- Gujarati

P. 16

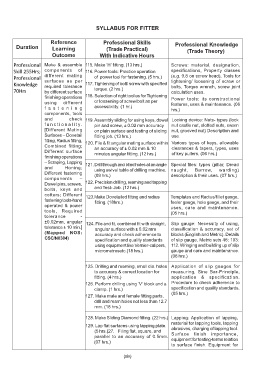

SYLLABUS FOR FITTER

Reference Professional Skills

Duration Learning (Trade Practical) Professional Knowledge

(Trade Theory)

Outcome With Indicative Hours

Professional Make & assemble 115. Make ‘H’ fitting. (13 hrs.) Screws: material, designation,

Skill 255Hrs; components of 116. Power tools: Practice operation specifications, Property classes

different mating (e.g. 9.8 on screw head), Tools for

Professional surfaces as per of power tool for fastening. (5 hrs.) tightening/ loosening of screw or

Knowledge required tolerance 117. Tightening of bolt/ screw with specified bolts, Torque wrench, screw joint

70Hrs by different surface torque. (2 hrs.) calculation uses.

finishing operations 118. Selection of right tool as for Tightening Power tools: its constructional

using different or loosening of screw/bolt as per features, uses & maintenance. (06

fastening accessibility. (1 hr.) hrs.)

components, tools

and check 119. Assembly sliding for using keys, dowel Locking device: Nuts- types (lock

functionality. pin and screw, ± 0.02 mm accuracy nut castle nut, slotted nuts, swam

[Different Mating on plain surface and testing of sliding nut, grooved nut) Description and

Surfaces – Dovetail fitting job. (13 hrs.) use.

fitting, Radius fitting, 120. File & fit angular mating surface within Various types of keys, allowable

Combined fitting; an accuracy of ± 0.02 mm & 10 clearances & tapers, types, uses

Different surface minutes angular fitting. (12 hrs.) of key pullers. (06 hrs.)

finishing operations

– Scraping, Lapping 121. Drill through and blind holes at an angle Special files: types (pillar, Dread

and Honing; using swivel table of drilling machine. naught, Barrow, warding)

Different fastening (09 hrs.) description & their uses. (07 hrs.)

components –

Dowel pins, screws, 122. Precision drilling, reaming and tapping

bolts, keys and and Test- Job. (12 hrs.)

cotters; Different 123.Make Dovetailed fitting and radius Templates and Radius/fillet gauge,

fastening tools-hand fitting. (18hrs.) feeler gauge, hole gauge, and their

operated & power uses, care and maintenance.

tools, Required (05 hrs.)

tolerance -

±0.02mm, angular 124. File and fit, combined fit with straight, Slip gauge: Necessity of using,

tolerance ± 10 min.] angular surface with ± 0.02 mm classification & accuracy, set of

(Mapped NOS: accuracy and check adherence to blocks (English and Metric). Details

CSC/N0304) specification and quality standards of slip gauge. Metric sets 46: 103:

using equipment like Vernier-calipers, 112. Wringing and building up of slip

micrometresetc.(18 hrs.) gauge and care and maintenance.

(06 hrs.)

125. Drilling and reaming, small dia. holes Application of slip gauges for

to accuracy & correct location for measuring, Sine Bar-Principle,

fitting. (4 hrs.) application & specification.

126. Perform drilling using ‘V’ block and a Procedure to check adherence to

clamp. (1 hrs.) specification and quality standards.

(05 hrs.)

127. Make male and female fitting parts,

drill and ream holes not less than 12.7

mm. (18 hrs.)

128. Make Sliding Diamond fitting. (22 hrs.) Lapping: Application of lapping,

material for lapping tools, lapping

129. Lap flat surfaces using lapping plate. abrasives, charging of lapping tool.

(5 hrs.)27. Filing flat, square, and Surface finish importance,

parallel to an accuracy of 0.5mm.

(07 hrs.) equipment for testing-terms relation

to surface finish. Equipment for

(xiv)