Page 13 - Fitter - 2nd Yr TP - Telugu

P. 13

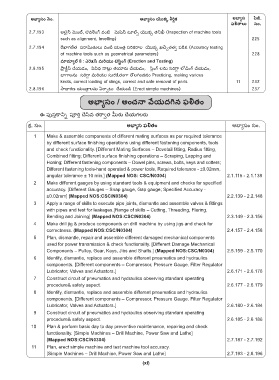

అభ్ాయాసం న�ం. అభ్ాయాసం యొకకి శీరిషిక అభ్ాయాస పేజీ.

ఫల్త్ఘలు సం.

2.7.193 అలై�నన్ మెంట్, లై�వలింగ్ వంట్ి మెష్టన్ ట్్యల్సి యొక్కు తన్ఖీ (Inspection of machine tools

such as alignment, levelling) 225

2.7.194 రై్మఖ్ాగణిత ప్రైామితులైు వంట్ి యంత్ర ప్రైిక్రైాలై యొక్కు ఖ్చి్చితత్వ ప్రైీక్ష (Accuracy testing

of machine tools such as geometrical parameters) 228

మ్్యడ్్యయాల్ 8 : ఎరెక్షన్ మ్రియు ట్్సి్టంగ్ (Erection and Testing)

2.8.195 పా్ర కీ్ట్స్ చ్యయడం, వివిధ్ న్డట్్ట్ల తయార్ు చ్యయడం, స్్ట్లంగ్ లైను స్రైిగా్గ లైోడింగ్ చ్యయడం,

భాగాలైను స్రైిగా్గ మరైియు స్ుర్క్ితంగా త్ొలైగించడం Practicing, making various

knots, correct loading of slings, correct and safe removal of parts 11 232

2.8.196 స్ాధ్డర్ణ యంత్్డ్ర లైను ఏరైా్పట్్ట చ్యయండి (Erect simple machines) 237

అభ్ాయాసం / అంచన్ఘ వైేయదగిన ఫల్త్ం

ఈ ప్ుస్తికాన్ై ప్ూరైితి చ్యస్్టన తరైా్వత మీర్ు చ్యయగలైర్ు

క్రా. స్ం. అభ్ాయాస ఫల్త్ం అభాయూస్ం స్ం.

1 Make & assemble components of different mating surfaces as per required tolerance

by different surface finishing operations using different fastening components, tools

and check functionality. [Different Mating Surfaces – Dovetail fitting, Radius fitting,

Combined fitting; Different surface finishing operations – Scraping, Lapping and

Honing; Different fastening components – Dowel pins, screws, bolts, keys and cotters;

Different fastening tools-hand operated & power tools, Required tolerance - ±0.02mm,

angular tolerance ± 10 min.] (Mapped NOS: CSC/N0304) 2.1.115 - 2.1.138

2 Make different gauges by using standard tools & equipment and checks for specified

accuracy. [Different Gauges – Snap gauge, Gap gauge; Specified Accuracy -

±0.02mm] (Mapped NOS:CSC/N0304) 2.2.139 - 2.2.148

3 Apply a range of skills to execute pipe joints, dismantle and assemble valves & fittings

with pipes and test for leakages.[Range of skills – Cutting, Threading, Flaring,

Bending and Joining] (Mapped NOS:CSC/N0304) 2.3.149 - 2.3.156

4 Make drill jig & produce components on drill machine by using jigs and check for

correctness. (Mapped NOS:CSC/N0304) 2.4.157 - 2.4.158

5 Plan, dismantle, repair and assemble different damaged mechanical components

used for power transmission & check functionality. [Different Damage Mechanical

Components – Pulley, Gear, Keys, Jibs and Shafts.] (Mapped NOS:CSC/N0304) 2.5.159 - 2.5.170

6 Identify, dismantle, replace and assemble different pneumatics and hydraulics

components. [Different components – Compressor, Pressure Gauge, Filter Regulator

Lubricator, Valves and Actuators.] 2.6.171 - 2.6.176

7 Construct circuit of pneumatics and hydraulics observing standard operating

procedure& safety aspect. 2.6.177 - 2.6.179

8 Identify, dismantle, replace and assemble different pneumatics and hydraulics

components. [Different components – Compressor, Pressure Gauge, Filter Regulator

Lubricator, Valves and Actuators.] 2.6.180 - 2.6.184

9 Construct circuit of pneumatics and hydraulics observing standard operating

procedure& safety aspect. 2.6.185 - 2.6.186

10 Plan & perform basic day to day preventive maintenance, repairing and check

functionality. [Simple Machines – Drill Machine, Power Saw and Lathe]

(Mapped NOS:CSC/N0304) 2.7.187 - 2.7.192

11 Plan, erect simple machine and test machine tool accuracy.

[Simple Machines – Drill Machine, Power Saw and Lathe] 2.7.193 - 2.8.196

(xi)