Page 242 - Content.pmd

P. 242

Bod ùYp¥e¡u Ïû\TôÓLs (Faults in arc welding)

úSôdLeLs: ClTôPj§u Ø¥®p ¿eLs ùT\ úYi¥V A±Ü §\uLs

• ùYpÓùUu¥u LiÔdÏj ùR¬kR Utßm ùR¬VôR Ïû\TôÓLû[d áßRp.

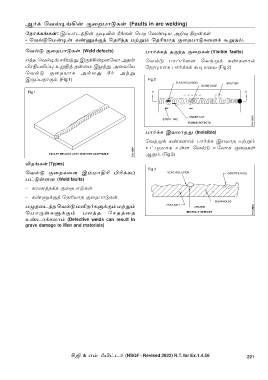

ùYpÓ Ïû\TôÓLs (Weld defects) TôodLj RÏkR Ïû\Ls (Visible faults)

GkR ùYp¥e N¬Vtß CÚd¡u\]úYô ARu ùYpÓ TWl©û] ùYtßd LiL[ôp

©W§TXõl× Eߧj RuûU CZkÕ AûYúV úSW¥VôL TôodLd á¥VûY (Fig 2)

ùYpÓ Ïû\VôL ApXÕ ºo Atß

CÚlTRôÏm. (Fig 1)

TôodL CVXôRÕ (Invisible)

ùYtßd LiL[ôp TôodL CVXôR Utßm

Eh×\UôL Es[ ùYpÓ EúXôL Ïû\Ls

BÏm. (Fig 3)

®ReLs (Types)

ùYpÓ Ïû\Lû[ CmUô§¬ ©¬dLl

ThÓs[] (Weld faults)

– LôQjRdL Ïû\TôÓLs

– LiÔdÏj ùR¬VôR Ïû\TôÓLs.

TÝRûPkR ùYpÓ U²RoLÞdÏm Utßm

ùTôÚsLÞdÏm TXjR úNRjûR

EiPôdLXôm (Defective welds can result in

grave damage to Men and materials)

£_õ & Gm: @©hPo (NSQF - Revised 2022) R.T. for Ex.1.4.56 221