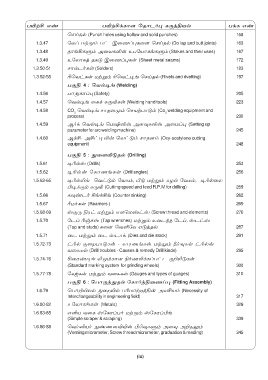

Page 11 - Content.pmd

P. 11

T«t£ Gi T«t£dLô] ùRôPo× LÚj§Vp TdL Gi

ùNnRp (Punch holes using hollow and solid punches) 158

1.3.47 úXl Utßm Th CûQl×Lû[ ùNnRp (Do lap and butt joints) 163

1.3.48 Rôe¡LÞm AûYL°u ETúVôLeLÞm (Stakes and their uses) 167

1.3.49 EúXôLj RLÓ CûQl×Ls (Sheet metal seams) 172

1.3.50-51 NôpPoLs (Solders) 183

1.3.52-55 ¬ùYhLs Utßm ¬ùYh¥e ùNnRp (Rivets and rivetting) 197

Tϧ 4 : ùYp¥e (Welding)

1.4.56 TôÕLôl× (Safety) 205

1.4.57 ùYp¥e ûLd LÚ®Ls (Welding hand tools) 223

1.4.58 CO ùYp¥e NôR]Øm ùNVtTôÓm (Co welding equipment and

2 2

process) 230

1.4.59 Bod ùYp¥e ùUμ²u A[ÜL°u AûUl× (Setting up

parameter for arc welding machine) 245

1.4.60 Bd£þ A£h¥Xõu ùYhÓm NôR]m (Oxy-acetylene cutting

equipment) 248

Tϧ 5 : Õû[«ÓRp (Drilling)

1.5.61 ¥¬pv (Drills) 253

1.5.62 ¥¬p-u úLôQeLs (Drill angles) 256

1.5.63-65 ¥¬pXõe - ùYhÓm úYLm, ÀÓ Utßm ÑZp úYLm, ¥¬pûX

©¥dÏm LÚ® (Cutting speed and feed R.P.M for drilling) 259

1.5.66 LÜiPo £ed¡e (Counter sinking) 262

1.5.67 ÃUoLs (Reamers ) 269

1.5.68-69 vÏÚ §Wh Utßm GXùUihv (Screw thread and elements) 276

1.5.70 úPl ¬gNv (Tap wrenches) Utßm EûPkR úPl, vPhv

(Tap and studs) Lû[ ùY°úV GÓjRp 287

1.5.71 ûP Utßm ûP vPôd (Dies and die stock) 291

1.5.72-73 h¬p Ïû\TôÓLs þ LôWQeLs Utßm ¾oÜLs h¬p-u

YûLLs (Drill troubles - Causes & remedy Drill kinds) 295

1.5.74-76 ¡ûWi¥e ÅÛdLô] ¨oQ«dLlThP ϱÂÓLs

(Standard marking system for grinding wheels) 300

1.5.77-78 úLwLs Utßm YûLLs (Gauges and types of guages) 310

Tϧ 6 : ùTôÚjÕRp úLôoj§ûQl× (Fitting Assembly)

1.6.79 ùTô±«Vp Õû\«p T¬Uôt\j§u AY£Vm (Necessity of

Interchangeability in engineering field) 317

1.6.80-82 EúXôLeLs (Metals) 329

1.6.83-85 G°V YûL vúLWlTo Utßm vúLWl©e

(Simple scraper & scraping) 339

1.6.86-88 ùYo²Vo ÖiQ[®«u ©¬ÜLÞm A[Ü A±RÛm

(Verning micrometer, Screw thread micrometer, graduation & reading) 345

(ix)