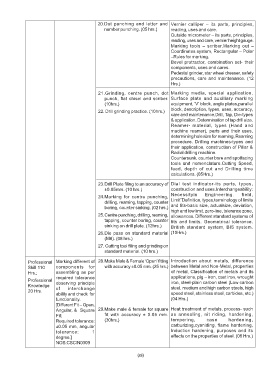

Page 14 - TDM - 1st Year - TT - Hindi

P. 14

20.Dot punching and letter and Vernier calliper – its parts, principles,

number punching. (05 hrs.) reading, uses and care.

Outside micrometer – its parts, principles,

reading, uses and care, vernier height gauge.

Marking tools – scriber.Marking out –

Coordinates system, Rectangular – Polar

–Rules for marking.

Bevel protractor, combination set- their

components, uses and cares.

Pedestal grinder, star wheel dresser, safety

precautions, care and maintenance. (12

Hrs.)

21.Grinding, centre punch, dot Marking media, special application.

punch, flat chisel and scriber. Surface plate and auxiliary marking

(10hrs.) equipment, ‘V’ block, angle plates,parallel

block, description, types, uses, accuracy,

22. Drill grinding practice. (10hrs.)

care and maintenance.Drill, Tap, Die-types

& application. Determination of tap drill size.

Reamer- material, types (Hand and

machine reamer), parts and their uses,

determining hole size for reaming, Reaming

procedure. Drilling machines-types and

their application, construction of Pillar &

Radial drilling machine.

Countersunk, counter bore and spotfacing

tools and nomenclature.Cutting Speed,

feed, depth of cut and Drilling time

calculations. (05Hrs.)

23.Drill Plate filing to an accuracy of Dial test indicator-its parts, types,

±0.05mm. (10 hrs.) construction and uses.Interchangeability:

24.Marking for centre punching, Necessityin Engineering. field,

drilling, reaming, tapping, counter LimitˆDefinition, types,terminology of limits

boring, counter sinking. (02 hrs.) and fits-basic size, actualsize, deviation,

high and low limit, zero-line, tolerance zone,

25.Centre punching, drilling, reaming, allowances. Different standard systems of

tapping, counter boring, counter fits and limits. Geometrical tolerance.

sinking on drill plate. (12hrs.) British standard system, BIS system.

26.Die pass on standard material (10Hrs.)

(M8). (08 hrs.)

27. Cutting tool filing and grinding on

standard material. (10 hrs.)

Professional Marking different of 28.Make Male & Female ‘Open’ fitting Introduction about metals, difference

Skill 110 components for with accuracy ±0.05 mm. (25 hrs.) between Metal and Non-Metal, properties

Hrs.; assembling as per of metal, Classification of metals and its

required tolerance applications, pig – iron, cast iron, wrought

Professional iron, steel-plain carbon steel (Low carbon

Knowledge observing principle steel, medium and high carbon steels, high

20 Hrs. of interchange

ability and check for speed steel, stainless steel, carbides, etc.)

functionality. (04 Hrs.)

[Different Fit – Open,

Angular, & Square 29.Make male & female for square Heat treatment of metals, process- such

Fit; fit with accuracy ± 0.05 mm. as annealing, nit riding, hardening,

Required tolerance: (30hrs.) tempering, case hardening,

±0.05 mm, angular carburizing,cyaniding, flame hardening,

tolerance: 1 Induction hardening, purposes and its

degree.] effects on the properties of steel. (08 Hrs.)

NOS:CSC/N0309

(xii)