Page 139 - Fitter 2nd Year TT - Telugu

P. 139

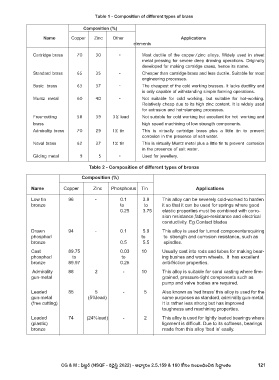

Table 1 - Composition of different types of brass

Composition (%)

Name Copper Zinc Other Applications

elements

Cartridge brass 70 30 - Most ductile of the copper/zinc alloys. Widely used in sheet

metal pressing for severe deep drawing operations. Originally

developed for making cartridge cases, hence its name.

Standard brass 65 35 - Cheaper than cartridge brass and less ductile. Suitable for most

engineering processes.

Basic brass 63 37 - The cheapest of the cold working brasses. It lacks ductility and

is only capable of withstanding simple forming operations.

Muntz metal 60 40 - Not suitable for cold working, but suitable for hot-working.

Relatively cheap due to its high zinc content. It is widely used

for extrusion and hot-stamping processes.

Free-cutting 58 39 3% lead Not suitable for cold working but excellent for hot working and

brass high speed machining of low strength components.

Admirality brass 70 29 1% tin This is virtually cartridge brass plus a little tin to prevent

corrosion in the presence of salt water.

Naval brass 62 37 1% tin This is virtually Muntz metal plus a little tin to prevent corrosion

in the presence of salt water.

Gilding metal 9 5 - Used for jewellery.

Table 2 - Composition of different types of bronze

Composition (%)

Name Copper Zinc Phosphorus Tin Applications

Low tin 96 - 0.1 3.9 This alloy can be severely cold-worked to harden

bronze to to it so that it can be used for springs where good

0.25 3.75 elastic properties must be combined with corro-

sion resistance,fatigue-resistance and electrical

conductivity. Eg.Contact blades

Drawn 94 - 0.1 5.9 This alloy is used for turned componentsrequiring

phosphor/ to to strength and corrosion resistance, such as

bronze 0.5 5.5 spindles.

Cast 89.75 0.03 10 Usually cast into rods and tubes for making bear-

phosphor/ to to ing bushes and worm wheels. It has excellent

bronze 89.97 0.25 anti-friction properties.

Admirality 88 2 - 10 This alloy is suitable for sand casting where fine-

gun-metal grained, pressure-tight components such as

pump and valve bodies are required.

Leaded 85 5 - 5 Also known as ‘red brass’ this alloy is used for the

gun-metal (5%lead) same purposes as standard, admirality gun-metal.

(free cutting) It is rather less strong but has improved

toughness and machining properties.

Leaded 74 (24%lead) - 2 This alloy is used for lightly loaded bearings where

(plastic) lignment is difficult. Due to its softness, bearings

bronze made from this alloy ‘bed in’ easily.

CG & M : ఫిట్్టర్ (NSQF - రివ�ైస్డ్ 2022) - అభ్్యయాసం 2.5.159 & 160 కోసం సంబంధించిన సిద్్ధ ధా ంతం 121