Page 20 - Fitter - 1st Year TP Telugu

P. 20

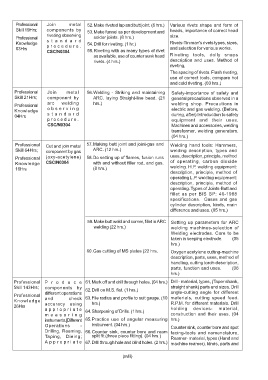

Professional Join metal 52.Make riveted lap and butt joint. (6 hrs.) Various rivets shape and form of

Skill 19Hrs; components by 53.Make funnel as per development and heads, importance of correct head

riveting observing size.

Professional solder joints. (8 hrs.)

Knowledge standard 54.Drill for riveting. (1 hr.) Rivets-Tin man's rivets types, sizes,

03Hrs procedure. and selection for various works.

CSC/N0304 55.Riveting with as many types of rivet

as available, use of counter sunk head Riveting tools, dolly snaps

rivets. (4 hrs.) description and uses. Method of

riveting,

The spacing of rivets. Flash riveting,

use of correct tools, compare hot

and cold riveting. (03 hrs.)

Professional Join metal 56.Welding - Striking and maintaining Safety-importance of safety and

Skill 21Hrs; component by ARC, laying Straight-line bead. (21 general precautions observed in a

arc welding hrs.) welding shop. Precautions in

Professional

Knowledge observing electric and gas welding. (Before,

04Hrs standard during, after) Introduction to safety

procedure. equipment and their uses.

CSC/N0304 Machines and accessories, welding

transformer, welding generators.

(04 hrs.)

Professional Cut and join metal 57.Making butt joint and joint-gas and Welding hand tools: Hammers,

Skill 64Hrs; component by gas ARC. (12 hrs.) welding description, types and

Professional (oxy-acetylene) 58.Do setting up of flames, fusion runs uses, description, principle, method

Knowledge CSC/N0304 with and without filler rod, and gas. of operating, carbon dioxide

16Hrs (8 hrs.) welding. H.P. welding equipment:

description, principle, method of

operating L.P. welding equipment:

description, principle, method of

operating. Types of Joints-Butt and

fillet as per BIS SP: 46-1988

specifications. Gases and gas

cylinder description, kinds, main

difference and uses. (05 hrs.)

59.Make butt weld and corner, fillet in ARC Setting up parameters for ARC

welding (22 hrs.) welding machines-selection of

Welding electrodes. Care to be

taken in keeping electrode. (05

hrs.)

60.Gas cutting of MS plates (22 hrs. Oxygen acetylene cutting-machine

description, parts, uses, method of

handling, cutting torch-description,

parts, function and uses. (06

hrs.)

Professional Produce 61.Mark off and drill through holes. (04 hrs.) Drill- material, types, (Taper shank,

Skill 143Hrs; components by 62.Drill on M.S. flat. (1 hrs.) straight shank) parts and sizes. Drill

different operations angle-cutting angle for different

Professional 63.File radius and profile to suit gauge. (10 materials, cutting speed feed.

Knowledge and check hrs.) R.P.M. for different materials. Drill

26Hrs accuracy using

appropriate 64.Sharpening of Drills. (1 hrs.) holding devices- material,

measuring construction and their uses. (04

instruments.[Different 65.Practice use of angular measuring hrs.)

Operations - instrument. (04 hrs.) Counter sink, counter bore and spot

Drilling, Reaming, 66.Counter sink, counter bore and ream facing-tools and nomenclature,

Taping, Dieing; split fit (three piece fitting). (04 hrs.) Reamer- material, types (Hand and

Appropriate 67.Drill through hole and blind holes. (2 hrs.) machine reamer), kinds, parts and

(xviii)