Page 62 - Plumber- TT - 1st Year - Tamil

P. 62

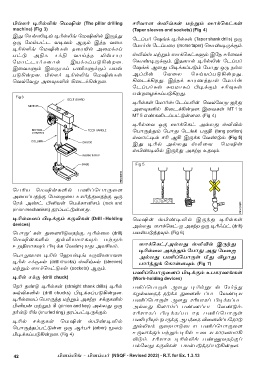

©pXo ¥¬pXõe ùUμu (The pillar drilling N¬Yô] vÄqLs Utßm ^ôdùLhLs

machine) (Fig 3) (Taper sleeves and sockets) (Fig 4)

CÕ ùNu³¥q ¥¬pXõe ùUμ²p CÚkÕ

úPlTo ú`ed ¥¬pLs (Taper shank drills) JÚ

JÚ úUmThP Y¥Ym BÏm CkR YûL

úUôov úPlTûW (morse taper) ùLôi¥ÚdÏm.

¥¬pXõe ùUμuLs RûW«p AûUdLl

ThÓ A§L Nd§ YônkR ªuNôW vÄqv Utßm ^ôdùLhLÞm CúR N¬ûYd

úUôhPôoL[ôp CVdLlTÓ¡u\]. ùLôi¥ÚdÏm. CR]ôp ¥¬pXõu úPlTo

CûYLÞm CXÏWLl T¦LÞdÏl TVu ú`ed B]Õ ©¥dLlTÓm úTôÕ JÚ SpX

TÓ¡u\]. ©pXo ¥¬pXõe ùUμuLs Bl©u úYûX ùNnVlTÓ¡u\Õ.

ùYqúYß A[ÜL°p ¡ûPd¡u\]. ¡ûPd¡\Õ. CkRd LôWQjRôp úUôov

úPlToLs ÑVUôLl ©¥dÏm N¬ÜLs

Gu\ûZdLlTÓ¡\Õ.

¥¬pLs úUôov úPlT¬u ùYqúYß IkÕ

A[ÜL°p ¡ûPd¡u\]. CûYLs MT 1 to

MT 5 GiL°PlThÓs[]. (Fig 4)

¥¬pûX JÚ ^ôdùLh ApXÕ vÄ®p

ùTôÚjÕm úTôÕ úPed Tϧ (tang portion)

vXôh¥p N¬ B¡ CÚdL úYiÓm. (Fig 5)

CÕ ¥¬p ApXÕ vÄûY ùUμu

v©i¥Xõp CÚkÕ ALt\ ERÜm.

Fig 5

ùT¬V ùUμuL°p T¦lùTôÚû[

AûUlTRtÏ úUû_ûV EVojÕYRtÏ JÚ

úWd Aih ©²Vu ùUdLô²Nm (rack and

pinion mechanism) RWlThÓs[Õ.

¥¬pûXl ©¥dÏm LÚ®Ls (Drill - Holding ùUμu v©i¥Xõp CÚkÕ ¥¬pLs

devices) ApXÕ ^ôdùLh-I ALt\ JÚ ¥¬@lh (drift)

ùTôÚhLs Õû[«ÓYRtÏ, ¥¬pûX (drill) TVuTÓjRÜm. (Fig 6)

ùUμuL°p ÕpXõVUôLÜm Utßm

EߧVôLÜm ©¥dL úYi¥VÕ AY£Vm. ^ôdùLh/ApXÕ vÄ®p CÚkÕ

¥¬pûX ALtßm úTôÕ AÕ úUû_

ùTôÕYô] ¥¬p úaôp¥e LÚ®L[ôY] ApXÕ T¦lùTôÚs ÁÕ ®ZôÕ

¥¬p NdÏLs (drill chucks) vÄqLs (sleeves) TôojÕd ùLôs[Üm. (Fig 7)

Utßm ^ôdùLhÓLs (sockets) BÏm.

T¦lùTôÚû[l ©¥dÏm ETLWQeLs

¥¬p NdÏ (drill chuck) (Work-holding devices)

úSo RiÓ ¥¬pLs (straight shank drills) ¥¬p T²lùTôÚs B]Õ ¥¬pÛPu úNokÕ

Lq®L°p (drill chucks) ©¥dLlTÓ¡u\]. ÑZpYûRj RÓdL Õû[«PlTP úYi¥V

¥¬pûXl ùTôÚjR Utßm ALt\ NdÏL°p T¦lùTôÚs B]Õ N¬VôLl ©¥dLlTP

©²Vu Utßm ¸ (pinion and key) ApXÕ JÚ ApXÕ ¡[ôml TiQlTP úYiÓm.

SopÓ ¬e (knurled ring) RWlTh¥ÚdÏm. N¬VôLl ©¥dLlTPôR T¦lùTôÚs

¥¬p NdÏLs ùUμu v©i¥Xõp T¦×¬Ùm STÚdÏ BTjûR ®û[®lTúRôÓ

ùTôÚjRlThÓs[ JÚ BoTo (arbor) êXm ÕpXõVd Ïû\TôÓûPV T¦lùTôÚû[

©¥dLlTÓ¡u\]. (Fig 4) EÚYôdÏm Utßm ¥¬p EûPV LôWQUô¡

®Óm. N¬VôL ¥¬pXõe TiÔYRtÏl

TpúYß LÚ®Ls TVuTÓjRlTÓ¡u\].

42 ©[m©e þ ©[mTo (NSQF - Revised 2022) - R.T. for Ex. 1.3.13