Page 93 - Content.pmd

P. 93

£_õ & Gm (CG & M) T«t£ 1.2.21 dLô] ùRôPo×d LÚj§Vp

@©hPo (Fitter) - A¥lTûP ùTôÚjÕRp (Basic Fitting)

Ï°okR £Np (Cold chisel)

úSôdLeLs: ClTôPj§u Ø¥®p ¿eLs ùT\ úYi¥V A±Ü §\uLs

• JÚ Ï°okR £NXõu TVuLû[l Th¥VXõÓRp

• JÚ úLôpÓ £NXõu TôLeL°u ùTVo A±Rp

Scan the QR Code to view

• £NXõu ùYqúYß YûLLû[d A±Rp the video for this exercise

• £NXõu ®YWd ϱl×Ls.

ùNÕdÏRp (chipping) Utßm ùYhÓRÛdÏ £NpLs, ûa LôoTu v¼p (high carbon steel)

ùTôÚjÕSWôp TVu TÓjRlTÓm ûLd LÚ® ApXÕ ÏúWôm ùY]¥Vm v¼p-Bp

úLôpÓ £Np (cold chisel) BÏm. (Fig 1) (chrome venadiam steel) ùNnVlTh¥ÚdÏm.

£NXõu ÏßdÏ ùYhÓj úRôt\m B]Õ

YZdLUôL AßeúLôQUôL(hexagonal) ApXÕ

Gi úLôQUôL (octagonal) CÚdÏm. CRu

ùYhÓm ®°m× B]Õ L¥]lTÓjRlThÓ

TRl TÓjRlTh¥ÚdÏm.

£NpL°u ùTôÕYô] YûLLs (Common

types of chisels)

¡NpLs IkÕ (5) ùTôÕYô] YûLL[ôL

Es[].

• @l[ôh £Np (Flat chisel/RhûPVô] £Np)

• ¡WôvþLh £Np (Cross-cut chisel)

• AûWYhP êdÏ £Np (Half round nose chisel)

JÚ £Np Utßm Ñj§Vp ER®Vôp A§Ll • ûYW Øû] £Np (Diamond point chisel)

T¥Vô] EúXôLjûR ALtßm ùNVp,

• ùYl £Np (Web chisel)

ùNÕdÏRp G]lTÓm. ùNÕdLlThP TWl×

LWÓ ØWPôL CÚlTRôp ARû] @ûTXõe @l[ôh £Np (Flat Chisel) (Fig 3a)

(filing) ùNnÕ Ø¥Ü ùNnV úYiÓm. ùT¬V RhûPVô] TWl×L°p CÚkÕ

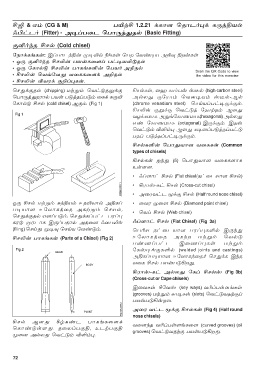

£NXõu TôLeLs (Parts of a Chisel) (Fig 2) EúXôLjûR ALt\ Utßm ùYpÓ

TiQlThP CûQl×Ls Utßm

úLv¥eÏL°p (welded joints and castings)

A§LlT¥Vô] EúXôLjûRf ùNÕdL CkR

YûL £Np TVuTÓ¡\Õ.

¡WôvþLh ApXÕ úLl £Npv (Fig 3b)

(Cross-cut or Cape chisels)

CûYLs ¸úYv (key ways) Y¬lTs[eLs

(grooves) Utßm Lô¥Ls (slots) ùYhÓYRtÏl

TVuTÓ¡u\].

AûW YhP êdÏ £NpLs (Fig 4) (Half round

nose chisels)

£Np B]Õ ¸rLiP TôLeLû[d

Yû[kR Y¬lTs[eLû[ (curved grooves) (oil

ùLôiÓs[Õ. RûXlTϧ, EPtTϧ

grooves) ùYhÓYRtÏ TVuTÓ¡\Õ.

Øû] ApXÕ ùYhÓm ®°m×.

72