Page 20 - Content.pmd

P. 20

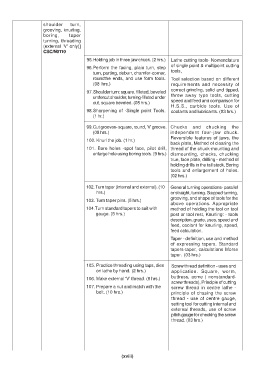

shoulder turn,

grooving, knurling,

boring, taper

turning, threading

(external 'V' only)]

CSC/N0110

95.Holding job in three jaw chuck. (2 hrs.) Lathe cutting tools- Nomenclature

96.Perform the facing, plain turn, step of single point & multipoint cutting

turn, parting, deburr, chamfer-corner, tools,

roundthe ends, and use form tools. Tool selection based on different

(08 hrs.) requirements and necessity of

correct grinding, solid and tipped,

97.Shoulder turn: square, filleted, beveled

undercut shoulder, turning-filleted under throw away type tools, cutting

cut, square beveled. (08 hrs.) speed and feed and comparison for

H.S.S., carbide tools. Use of

98.Sharpening of -Single point Tools. coolants and lubricants. (03 hrs.)

(1 hr.)

99.Cut grooves- square, round, 'V' groove. Chucks and chucking the

(08 hrs.) independent four-jaw chuck.

Reversible features of jaws, the

100. Knurl the job. (1 hr.)

back plate, Method of clearing the

101. Bore holes -spot face, pilot drill, thread of the chuck-mounting and

enlarge hole using boring tools. (9 hrs.) dismounting, chucks, chucking

true, face plate, drilling - method of

holding drills in the tail stock, Boring

tools and enlargement of holes.

(02 hrs.)

102. Turn taper (internal and external). (10 General turning operations- parallel

hrs.) or straight, turning. Stepped turning,

grooving, and shape of tools for the

103. Turn taper pins. (5 hrs.)

above operations. Appropriate

104.Turn standard tapers to suit with method of holding the tool on tool

gauge. (5 hrs.) post or tool rest, Knurling: - tools

description, grade, uses, speed and

feed, coolant for knurling, speed,

feed calculation.

Taper - definition, use and method

of expressing tapers. Standard

tapers-taper, calculations Morse

taper. (03 hrs.)

105. Practice threading using taps, dies Screw thread definition - uses and

on lathe by hand. (2 hrs.) application. Square, worm,

106. Make external ‘V’ thread. (8 hrs.) buttress, acme ( nonstandard-

screw threads), Principle of cutting

107. Prepare a nut and match with the screw thread in centre lathe -

bolt. (10 hrs.) principle of chasing the screw

thread - use of centre gauge,

setting tool for cutting internal and

external threads, use of screw

pitch gauge for checking the screw

thread. (03 hrs.)

(xviii)