Page 83 - Electrician -1st Year - TT

P. 83

YûL CûQl× úTôu\úR, B]ôp CRu LXûYVôp (Solder) (CRu EÚÏ ¨ûX NôpPo

ùRôeÏm Lm©Vô]Õ Ød¡VUô] Lm©«u ùNnVlTÓm EúXôLjûR ®P Ïû\Ü)

ÁÕ G°RôL SLÚm YûL«p ¿[Uô] CûQdÏm ùNVpTôh¥tÏ NôpP¬e

CûQlTôp B]Õ. (Soldering) G]lTÓm. EÚ¡V ¨ûX«XõÚdÏm

DVdLXûY (molten solder) Tt\ûYl×

ùTôÚ[ô] CWiÓ EúXôLeL°u

úUtTWl×L°p FÓÚ® ùUpXõV TPX

Y¥®p CûQd¡u\Õ.

NôpP¬e¡u AY£Vm (Necessity of soldering):

YVo Utßm úL©s CûQl×Ls ARu êXd

LPj§Lû[l úTôuú\ ªuLPjÕm

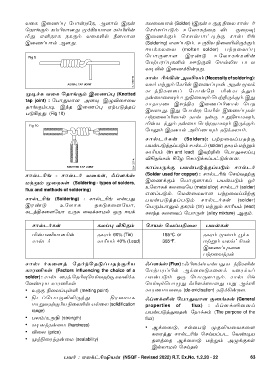

Ø¥fÑ YûL ùRôeÏm CûQl× (Knotted

RuûUûVÙm EߧûVÙm ùTt±ÚdÏm. CÕ

tap joint) : úTôÕUô] A[Ü CÝ®ûNûV

NôRôWQ CVk§W CûQl©]ôp ùT\

RôeÏmT¥ CkR CûQl× HtTÓjRl

CVXôÕ. CÕ úTôu\ úL©s CûQl×Ls

TÓ¡\Õ. (Fig 10)

Tt\ûYl©]ôp Rôu SuÏ EߧVôLÜm,

ªuLPjÕm RuûU ùTt\RôLÜm CÚdÏm.

úUÛm CR]ôp A¬lûTÙm RÓdLXôm.

NôpPoLs (Solders): Tt\ûYlTRtÏ

TVuTÓjRlTÓm NôpPo (solder) RLWm Utßm

LôÃVm (tin and lead) CYt±u ùTôÕLXl×

®¡ReLs ¸úZ ùLôÓdLlThÓs[].

LôlTÚdÏ TVuTÓjRlTÓm NôpPo

NôpP¬e þ NôpPo YûLs, @l[dv (Solder used for copper) : NôpP¬e ùNnYRtÏ

Utßm Øû\Ls (Soldering - types of solders, CûQdÏm ùTôÚ[ôLl TVuTÓm Ko

flux and methods of soldering) EúXôLd LXûYúV (metal alloy) NôpPo (solder)

G]lTÓm. ùUuûUVô] Tt\ûYl©tÏ

NôpP¬e (Soldering) : NôpP¬e GuTÕ TVuTÓjRlTÓm NôpPoLs (solder)

CWiÓ EúXôL RLÓLû[úVô, ùTÚmTôÛm RLWm (tin) Utßm LôÃVm (lead)

LPj§Lû[úVô EÚL ûYdLôUp JÚ DVd LXkR LXûYl ùTôÚs (alloy mixture) BÏm.

NôpPoLs LXl× ®¡Rm ùNVp ùYlT¨ûX TVuLs

ªuT¦Vô[¬u RLWm 60% (Tin) 185°C. or RLWm ØXôm éfÑ

NôpPo LôÃVm 40% (Lead) 365°F. Utßm GXdh¬Lp

CûQl×Lû[

Tt\ûYjRp

NôpPoLû[j úRokùRÓlTRtϬV @l[dv (Flux) : @©[dv GuTÕ LPj§L°u

LôW¦Ls (Factors influencing the choice of a úUtTWl©p Bdû^ÓLû[d LûWdLl

solder) : NôpPûWj ùR¬ÜùNnYRtÏ LY²dL TVuTÓm JÚ ùTôÚ[ôÏm. NôpP¬e

úYi¥V LôW¦Ls ùNnÙmùTôÝÕ @©[d^ô]Õ Uß Bd³

• EÚÏ ¨ûXl×s° (melting point) LôWQUôYûR (de-oxidisation) RÓd¡u\].

• §PlùTôÚ°XõÚkÕ §WYUôL @l[d³u ùTôÕYô] ÏQeLs (General

UôßYRtϬV ¨ûX«u GpûX (solidification properties of flux) : @l[d³û]l

range) TVuTÓjÕYRu úSôdLm (The purpose of the

• TXm/Eߧ (strength) flux)

• L¥]jRuûU (hardness)

• Bdû^Ó, NpûTÓ ØRXõVûYLû[

• ®ûX (price) LûWjÕ NôpP¬e ùNnVlTP úYi¥V

• Øj§ûWjRuûU (sealability) R[jûR Bdû^Ó Utßm AÝdÏLs

CpXôUp ùNnRp

TYo : GXdh¬μVu (NSQF - Revised 2022) R.T. Ex.No. 1.2.20 - 22 63