Page 16 - Mechanic Diesel - TP - Punjabi

P. 16

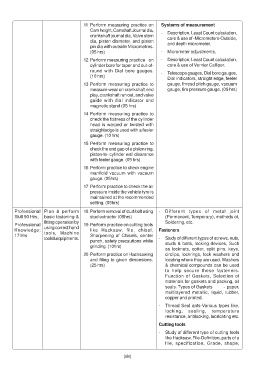

11 Perform measuring practice on Systems of measurement

Cam height, Camshaft Journal dia, - Description, Least Count calculation,

crankshaft journal dia, Valve stem care & use of -Micrometers-Outside,

dia, piston diameter, and piston and depth micrometer,

pin dia with outside Micrometres.

(05 hrs) - Micrometer adjustments,

12 Perform measuring practice on - Description, Least Count calculation,

cylinder bore for taper and out-of- care & use of Vernier Calliper.

round with Dial bore gauges. - Telescope gauges, Dial bore gauges,

(10 hrs)

Dial indicators, straight edge, feeler

13 Perform measuring practice to gauge, thread pitch gauge, vacuum

measure wear on crankshaft end gauge, tire pressure gauge. (09 hrs)

play, crankshaft run out, and valve

guide with dial indicator and

magnetic stand (05 hrs)

14 Perform measuring practice to

check the flatness of the cylinder

head is warped or twisted with

straightedge is used with a feeler

gauge. (10 hrs)

15 Perform measuring practice to

check the end gap of a piston ring,

piston-to- cylinder wall clearance

with feeler gauge. (09 hrs)

16 Perform practice to check engine

manifold vacuum with vacuum

gauge. (05hrs)

17 Perform practice to check the air

pressure inside the vehicle tyre is

maintained at the recommended

setting. (05hrs)

Professional Plan & perform 18 Perform removal of stud/bolt using - Different types of metal joint

Skill 90 Hrs; basic fastening & stud extractor (05hrs) (Permanent, Temporary), methods of,

fitting operation by Soldering, etc.

Professional 19 Perform practice on cutting tools

Knowledge; using correct hand like Hacksaw, file, chisel, Fasteners

17 Hrs tools, Machine Sharpening of Chisels, center

tools&equipments. - Study of different types of screws, nuts,

punch, safety precautions while studs & bolts, locking devices, Such

grinding. (10hrs)

as locknuts, cotter, split pins, keys,

20 Perform practice on Hacksawing circlips, lockrings, lock washers and

and filing to given dimensions. locating where they are used. Washers

(25 hrs) & chemical compounds can be used

to help secure these fasteners.

Function of Gaskets, Selection of

materials for gaskets and packing, oil

seals. Types of Gaskets - paper,

multilayered metallic, liquid, rubber,

copper and printed.

- Thread Seal ants-Various types like,

locking, sealing, temperature

resistance, antilocking, lubricating etc.

Cutting tools

- Study of different type of cutting tools

like Hacksaw, File-Definition, parts of a

file, specification, Grade, shape,

(xiv)