Page 21 - Welder -TT - Malayalam

P. 21

Professional Perform joining of OAW-01 97 Square butt joint on Copper sheet - Metalizing - types of met-

different similar and 2mm thick in flat position. (1G) alizing principles.

Skill 41 dissimilar metals by OAW-02 98 "T" joint on Copper to MS sheet - Manual Oxy - acetylene

Hrs; brazing operation as 2mm thick in flat position by powder coating

per standard process- principles of

Professional procedure. [different Brazing (1F) operation and

Knowledge similar and dissimilar applications

metals- Copper, MS,

10Hrs SS] OAW-03 99 Silver brazing on S.S Sheet with - Reading of assembly

copper sheet "T" joint. drawing

OAW-04

100 Silver brazing on copper tube to tube. - Welding Procedure

Specification (WPS) and

Procedure Qualification

Record ( PQR)

Professional Repair Cast Iron OAW-05 101Repair welding of broken C.I. - Hard facing/ surfacing

machine parts by machine parts by oxy-acetylene necessity, surface pre

Skill 24Hrs; selecting appropriate SMAW-01 welding with C.I and bronze filler rod. paration, various hard

Professional welding process. 102Repair welding of broken C.I machine facing alloys and a

[Appropriate welding SMAW-02 parts by C.I. electrode. dvantages of hard facing.

Knowledge process- OAW, SMAW] 103 Repair plastic broken parts or pipes - Plastic welding machine

01Hrs Hard facing of alloy steel by plastic welding machine. with hot air gun and

components / MS rod by plastic material:

using hard facing 104.Make a plastic tank with plastic sheet Polypropylene (PP)

of PVC. Dimensions 150*100*100

electrode.

Polyethylene (PE)

Polyvinylchloride (PVC)

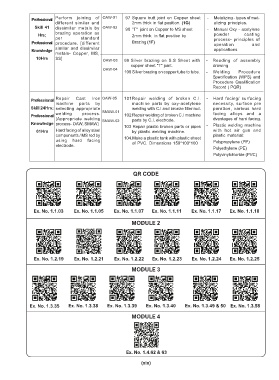

QR CODE

Ex. No. 1.1.03 Ex. No. 1.1.05 Ex. No. 1.1.07 Ex. No. 1.1.11 Ex. No. 1.1.17 Ex. No. 1.1.18

MODULE 2

Ex. No. 1.2.19 Ex. No. 1.2.21 Ex. No. 1.2.22 Ex. No. 1.2.23 Ex. No. 1.2.24 Ex. No. 1.2.25

MODULE 3

Ex. No. 1.3.35 Ex. No. 1.3.38 Ex. No. 1.3.39 Ex. No. 1.3.40 Ex. No. 1.3.49 & 50 Ex. No. 1.3.58

MODULE 4

Ex. No. 1.4.62 & 63

(xix)