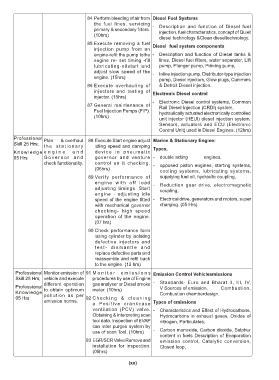

Page 22 - Mechanic Diesel - TP - Malayalam

P. 22

84 Perform bleeding of air from Diesel Fuel Systems

the fuel lines, servicing - Description and function of Diesel fuel

primary & secondary filters. injection, fuel characteristics, concept of Quiet

(10hrs)

diesel technology &Clean dieseltechnology.

85 Execute removing a fuel Diesel fuel system components

injection pump from an

engine-refit the pump tothe - Description and function of Diesel tanks &

engine re- set timing -fill lines, Diesel fuel filters, water separator, Lift

lubricating-oilstart and pump, Plunger pump, Priming pump,

adjust slow speed of the - Inline injection pump, Distributor-type injection

engine. (15hrs) pump, Diesel injectors, Glow plugs, Cummins

86 Execute overhauling of & Detroit Diesel injection.

injectors and testing of Electronic Diesel control

injector. (15hrs)

- Electronic Diesel control systems, Common

87 General maintenance of Rail Diesel Injection (CRDI) system,

Fuel Injection Pumps (FIP). hydraulically actuated electronically controlled

(10hrs) unit injector (HEUI) diesel injection system.

Sensors, actuators and ECU (Electronic

Control Unit) used in Diesel Engines. (12hrs)

Professional Plan & overhaul 88 Execute Start engine adjust Marine & Stationary Engine:

Skill 25 Hrs; th e sta ti o n a ry idling speed and damping

Knowledge engine and device in pneumatic Types,

05 Hrs Governor and governor and venture - double acting engines,

check functionality. control un it checking. - opposed piston engines, starting systems,

(06hrs) cooling systems, lubricating systems,

89 Verify performance of supplying fuel oil, hydraulic coupling,

engine with off load - Reduction gear drive, electromagnetic

adjusting timings. Start coupling,

engine - adjusting idle

speed of the engine fitted - Electrical drive, generators and motors, super

with mechanical governor charging. (05 Hrs)

checking- high speed

operation of the engine.

(07 hrs)

90 Check performance form

issing cylinder by isolating

defective injectors and

test- dismantle and

replace defective parts and

reassemble and refit back

to the engine. (12 hrs)

Professional Monitor emission of 91 M onit or emis sions Emission Control Vehicleemissions

Skill 25 Hrs; vehicle and execute procedures by use of Engine

different operation gas analyser or Diesel smoke - Standards- Euro and Bharat II, III, IV,

Professional to obtain optimum meter. (10hrs) V Sources of emission, Combustion,

Knowledge pollution as per Combustion chamberdesign.

05 Hrs 92 Checking & cleaning

emission norms. Types of emissions

a Positive crankcase

ventilation (PCV) valve. - Characteristics and Effect of Hydrocarbons,

Obtaining & interpreting scan Hydrocarbons in exhaust gases, Oxides of

tool data. Inspection of EVAP nitrogen, Particulates,

can inter purges system by

use of scan Tool. (10hrs) - Carbon monoxide, Carbon dioxide, Sulphur

content in fuels Description of Evaporation

93 EGR/SCR Valve Remove and emission control, Catalytic conversion,

installation for inspection. Closed loop,

(05hrs)

(xx)